TM 55-1520-240-23-4

5-81.1

REPLACE SHOCK ABSORBER BRACKET BUSHINGS

(Continued)

5-81.1

REAM LOWER BORE

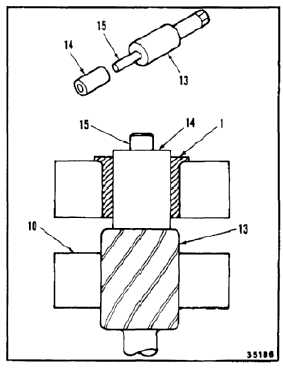

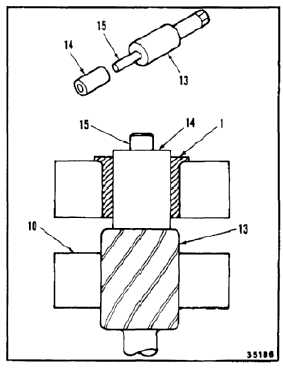

10.

Ream the lower bore for oversize bushing as

follows:

a.

Select proper reamer (13) from Table 1.

b.

Place sleeve (14) over reamer guide pin (15).

c.

Position blade so that shavings and debris

from reamer will not fall on the reamer guide

pin. Binding may result.

d.

Insert reamer guide pin (15) through bore

in lower plate (10) and engage it in upper

bushing (1). Hand ream the bore to size. Do

not attempt to remove more than 0.010 inch

of material with one cut of the reamer.

e.

Remove equipment from the blade. Clean

the bore and surrounding area. Use clean

cloths (E120) damp with acetone (E20).

Wear gloves (E184.1).

INSPECT

INSTALL LOWER BUSHING

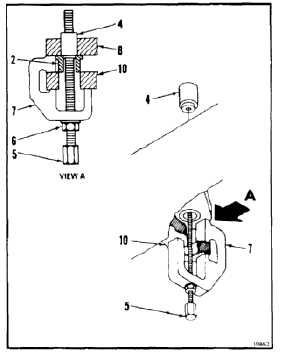

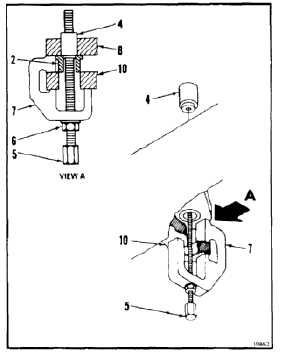

11.

Coat the outer surface of new bushing (2) with

epoxy primer (E292.1). Allow to air dry for 24

hours. Wear gloves (E184.1).

12.

Chill bushing (2) to -40ºF. Use a mixture of

dry ice (E92) in methanol (E243). Wear Kevlar

gloves (E187).

13.

Position pusher/puller yoke (7) on lower bracket

plate (10). Align hole in yoke with holes in

bracket plates.

14.

Place replacement bushing (2) between bracket

plates (8 and 10). Install rod (5), with nut (6),

through yoke (7), bushing (2) and upper plate (8).

15.

Thread pusher/guide (4) and rod (5) with small

pitot end toward bushing (2). Seat pusher/guide

in bushing.

5-462