TM 55-1520-240-23-4

5-81.1

REPLACE SHOCK ABSORBER BRACKET BUSHINGS

(Continued)

5-81.1

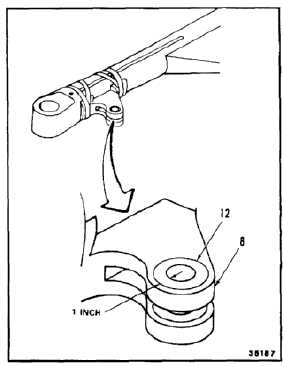

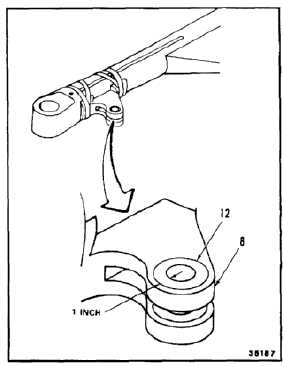

22.

Remove finish from upper plate (8) for 1 inch

around bushing bore (12). Use cloth (E120)

damp with acetone (E20). Wear gloves (E184.1).

23.

Inspect plate (8) in the area of finish removal for

condition as follows:

a.

If any damage in that area extends more than

0.030 inch from bushing bore (12), or bore is

elongated, reject the rotor blade.

b.

Measure bore (12) in two places; one parallel

to the blade and one at right angle to the

blade. If the bore is out of round by more

than 0.002 inch or exceeds the dimension for

any bushing listed in Table 1, it must be to the

next largest size shown in Table 1.

c.

If bore (12) matches any size shown in Table

1, proceed to step 24. Install the proper

bushing.

REAM UPPER BORE

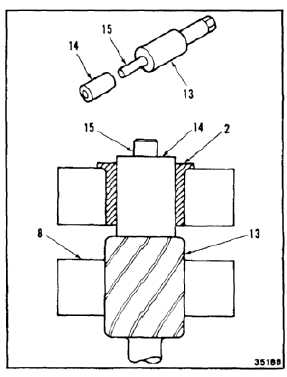

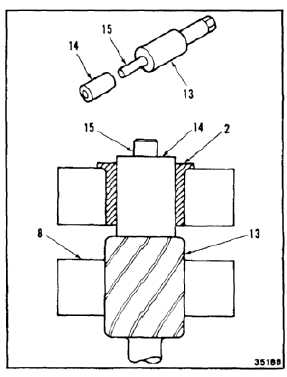

24.

Ream the upper bore for an oversize bushing

as follows:

a.

Select the proper reamer (13) from Table 1.

b.

Place sleeve (14) over reamer guide pin (15).

c.

Turn the blade over so that shavings and

debris from reamer (13) will not fall on reamer

guide pin (15). Binding may result.

d.

Insert reamer guide pin (15) through the

bore in upper plate (8) and engage it in lower

bushing (2). Hand ream the bore to size. Do

not attempt to remove more than 0.010 inch

of material with one cut of the reamer.

e.

Remove equipment from the blade. Clean

the bore and surrounding area. Use clean

cloths (E120) damp with acetone (E20).

Wear gloves (E184.1).

INSPECT

5-464