TM 55-1520-240-23-4

5-81.2

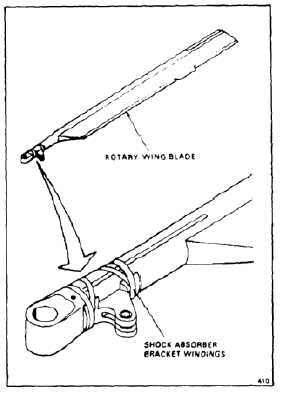

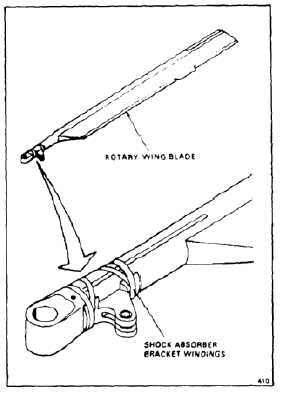

REPAIR KEVLAR SHOCK ABSORBER BRACKET WINDINGS — MINOR DAMAGE

5-81.2

INITIAL SETUP

Applicable Configurations:

All

Tools:

Heat Lamp

Respirator

Trip Balance, NSN 6670-00-401-7195

Materials:

Abrasive Paper (E7 and E9)

Acetone (E20)

Adhesive (E40, E41, E43, or E47.1)

Cloth (E120)

Gloves (E186)

Peel Ply (E270)

Polyethylene Cup (E157)

Tape, Glass Cloth (E387)

Teflon-Impregnated Fabric (E170)

Temperature Indicating Strips (E413)

Wood Spatula (E424)

Curing Agent (E158.1)

Personnel Required:

Aircraft Structural Repairer

Inspector

Equipment Condition:

Off Helicopter Task

General Safety Instructions:

Acetone (E20) is extremely flammable.

It can be toxic. Avoid inhaling. Use

only with adequate ventilation. Avoid

contact with skin, eyes, or clothing.

Keep away from heat, sparks, or open

flame. In case of contact, immediately

flush skin or eyes with water for

at least 15 minutes. Get medical

attention for eyes.

Adhesive used in the manufacturing of

some fiberglass rotor blades contain

asbestos. During blade repair, strict

adherence to all safety procedures

when working with asbestos must

be complied with (applies to blade

serial numbers A-1-0001 to 1465 and

A-2-0001 to 1473 only).

1.

Check depth of damage area (1). Depth shall

not exceed 0.005 inch. If damage is deeper

than 0.005 inch, return blade for disposition. If

damage is less than 0.005 inch deep, go to step

2.

Do not sand into filament windings.

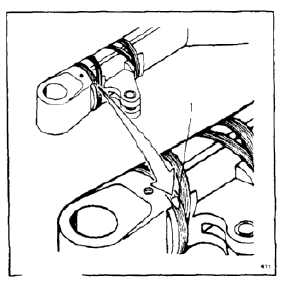

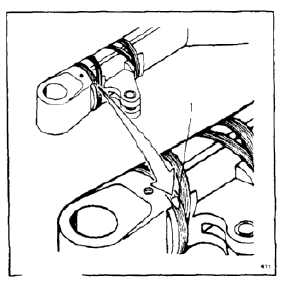

2.

Remove finish 1 inch around all sides of damage

area (1). Use abrasive paper (E7).

5-466