TM 55-1520-240-23-9

11-90.1

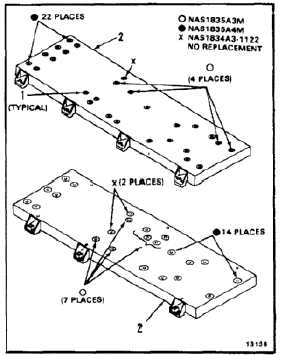

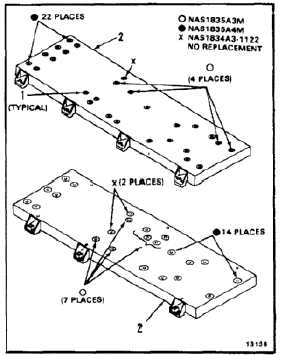

REPLACE INSERTS IN CONTROL PALLET STA 95 AND STA 120 (AVIM)

(Continued)

11-90.1

PREPARE PALLET

1.

Remove defective insert (1). If insert is loose

enough, carefully remove it by hand. Go to step

2. If insert is bonded into pallet, drill or bore out

insert as follows:

a.

Select suitable drill bit or counterbore.

Use 11/16 inch drill bit or counterbore for

NAS1835A3M inserts. Use 3/4 inch drill bit

or counterbore for NAS1835A4M inserts.

b.

Install boring tool in drill press. Adjust table

height.

c.

Limit depth of bore to at least 1/8 inch from

opposite face of pallet.

d.

Align insert to be drilled or bored out on drill

press table. Clamp pallet (2) in place. Use

C-clamps and wood blocks. Avoid excessive

clamping pressure.

e.

Set drill press to highest speed. Slowly drill

out insert. Remove pallet.

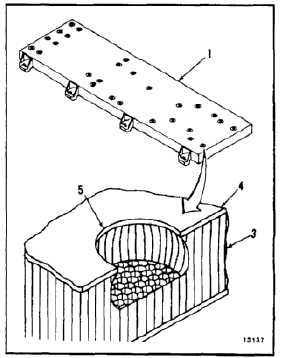

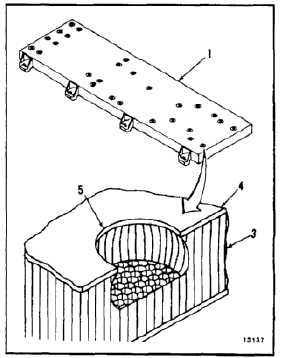

2.

Clamp pallet (1) to workbench. Use C-clamps

and wood blocks.

NOTE

Do not leave a smooth surface within

the bore. Proper adhesive bonding

requires a rough surface.

3.

Enlarge diameter of bore in honeycomb (3)

below surface plate (4). Do not enlarge hole (5)

in surface plate.

4.

Vacuum debris from hole (5). Clean the area

around the hole with a clean cloth (E120) damp

with acetone (E20) or methyl-ethyl-ketone

(E244). Wear gloves (E184.1) and goggles.

11-484