TM 55-1520-240-23-9

11-82

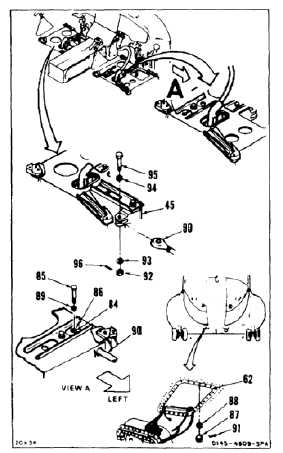

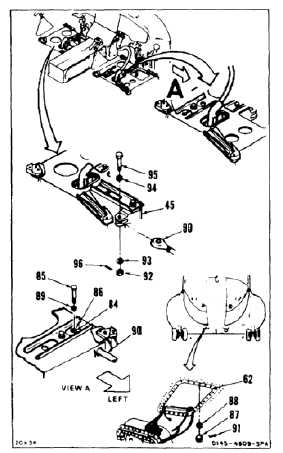

INSTALL COPILOT’S COCKPIT CONTROL ASSEMBLY

(Continued)

11-82

INSTALL ROLL CONNECTING LINK

52.

Position bellcrank (84) to align bolt (85) and hole

(86).

53.

Working through right access (62), remove nut

(87) and washer (88) from bolt (85).

54.

Have helper in cockpit remove bolt (85) and

washer (89).

55.

Slide roll connecting link (90) from left into

position in bellcrank (84). Check that link is free

of electrical wiring.

56.

Have helper install washer (89) and bolt (85) in

bellcrank (84) and hold bolt.

57.

Install washer (88) and nut (87) on bolt (85).

Remove tag from link (90).

58.

Torque nut (87) to 30 to 60 inch-pounds. Install

cotter pin (91).

59.

Working from cockpit, remove nut (92) two

washers (93 and 94), and bolt (95) from bellcrank

(45).

60.

Position link (90) in bellcrank (45).

61.

Install bolt (95), two washers (94 and 93), and

nut (92) in bellcrank (45).

62.

Torque nut (92) to 30 to 60 inch-pounds. Install

cotter pin (96).

63.

Check bolts (85 and 95). Bolts shall not rotate

with torque less than 10 inch-pounds. There

shall be no axial looseness. If bolt rotates or is

loose, add washer under nut, and repeat step

58 or 62.

11-434