TM 55-1520-240-23-10

16-110

INSTALL ENGINE AIR PARTICLE SEPERATOR

(Continued)

16-110

3.

Check rails for cleainliness and smooth surface

condition. Clean and/or repair surfaces as

necessary.

Diffuser duct is made of fiberglass

and can be easily damaged. Do not

place weight on EAPS on diffuser

duct. EAPS is made of lightweight

metal and has thousands of plastic

inlet swirl tubes. Surface contact

with hard objects can damage plastic

tubes and/or sheet metal surfaces.

4.

Place EAPS in horizontal position.

5.

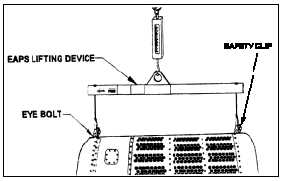

Attach EAPS Lifting Device (T188) to hoist and

position above EAPS. Connect cables to eye

bolts on EAPS secure with safety clips.

Lift EAPS carefully, avoid sudden

starts and stops. It may require

several persons to guide and steady

EAPS during lifting, alignment and

installation to prevent damage from

occurring to equipment.

6.

Lift EAPS until mounting feet are level and

parallel with rails.

Keeps hands clear of rails.

7.

Carefully move EAPS aft until both sets of

mounting feet are on rails. If mounting feet do not

align with rails, loosen inboard slide blocks, move

the EAPS aft and tighten slide blocks. Once

EAPS is on rails it must be able to be moved all

the way forward and aft on rails.

8.

Disconnect EAPS Lifting Device (T188) from

EAPS.

Perform FOD check around engine

inlet before moving EAPS to an aft

position.

9.

Slide EAPS aft until firmly seated against engine

nacelle. P-seal on EAPS must contact engine

D-ring at all points.

16-369