TM 55-1520-240-23-9

11-65

ASSEMBLE THRUST CONTROL (AVIM)

(Continued)

11-65

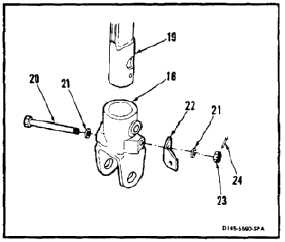

12.

Coat inside of large hole on top of end fitting (18)

with epoxy primer (E292). While primer is wet,

slide end fitting onto shaft (19). Align holes in

end fitting and shaft. Wear gloves (E184.1).

13.

Install bolt (20), two washers (21), clip (22) and

nut (23). Torque nut to 30 to 60 inch-pounds.

Install cotter pin (24).

14.

Check bolt (20). Bolt shall not rotate with torque

less than 10 inch-pounds. Bolt shall not have

axial looseness. If bolt rotates or is loose, add

washer (21) under nut (23). Torque and cotter

pin nut again.

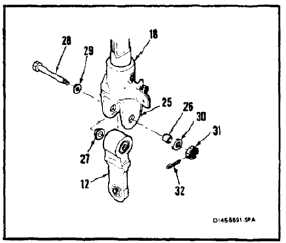

15.

Coat inside of holes in lugs (25) of end fitting (18)

with epoxy primer (E292). While primer is wet,

install bushing (26) and shoulder bushing (27).

Wear gloves (E184.1).

FLIGHT SAFETY PARTS

This is an installation critical flight

safety part. All aspects of its assembly

and installation must be ensured.

Ensure that both bearings and related

spacer are properly installed at upper

end of the link assembly.

Ensure single bearing is properly

installed and retained at the lower end

of the link assembly.

Ensure proper orientation of the link

assembly at installation.

At installation of this component,

ensure proper attaching hardware

(impedance type bolt, nut, and

washers) is installed including

verification of bolt head orientation,

torque, and installation of cotter pins.

Loose attachments within flight control

primary linkage will degrade aircraft

control. Missing components will

cause loss of control.

16.

Position link (12) in end fitting (18). Install bolt

(28), washers (29 and 30) and nut (31). Torque

nut to 30 to 60 inch-pounds. Install cotter pin

(32).

17.

Check bolt (28). Bolt shall not rotate with torque

less than 10 inch-pounds. Bolt shall not have

axial looseness. If bolt rotates or is loose, add

washer (30) under nut (31). Torque and cotter

pin nut again.

11-294