TM 55-1520-240-23-4

5-117.1

DISASSEMBLE AND INSPECT FWD AND AFT SWASHPLATE ASSEMBLY

BEARINGS (Continued)

5-117.1

ASSEMBLE SWASHPLATE

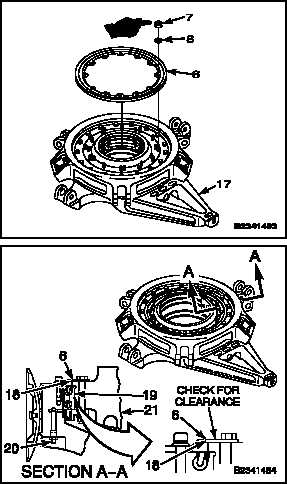

8.

For aft swashplate assembly only, assembly as

follows:

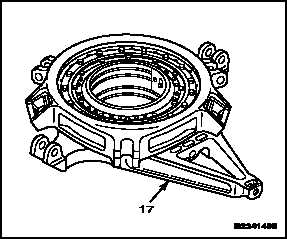

a.

Use cloths (E134.1) damp with acetone

(E20). Clean stationary ring assembly (17)

bolt hole threads. Wipe area dry with clean

cloth (E134.1). Wear gloves (E184.1).

b.

Position seal (6) on stationary ring (17).

c.

Coat 12 bolts (7) with epoxy primer (E292.1).

Wear gloves (E184.1).

d.

Install 12 bolts (7) wet with epoxy primer

(E292.1) and washers (8). Torque bolts to

260-280 inch-pounds. Lockwire bolts. Use

lockwire (E233).

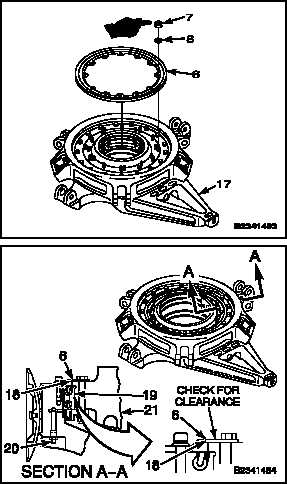

INSPECT

e.

Check that clearance between seal (6) and

seal (18) is 0.005 to 0.070 inch.

f.

Lubricate bearing (19) through fitting (20)

(Task 1-90). Use grease (E190). Turn rotating

ring (21) one full circle while greasing until a

fillet of grease appears between grease seals

(6 and 18). Use hand lubricating gun.

INSPECT

g.

Wipe off excess grease around stationary

grease seal. Use cloth (E134.1). Wear

gloves (E184.1).

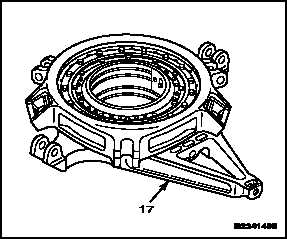

h.

Use cloths (E134.1) damp with acetone

(E20). Clean stationary ring assembly (17)

hardware. Wipe area dry with clean cloth

(E134.1). Wear gloves (E184.1).

i.

Touch up hardware using one coat of epoxy

primer (E292.1). Wear gloves (E184.1).

FOLLOW-ON MAINTENANCE:

Remove servocylinder safety blocks (Task 11-29).

Remove pitch link lockpins (Task 5-96.1).

END OF TASK

5-666.4

Change 2