TM 55-1520-240-23-4

5-120

REPAIR SWASHPLATE ROTATING RING (AVIM)

(Continued)

5-120

NOTE

Procedure is same to repair forward

or aft swashplate rotating rings.

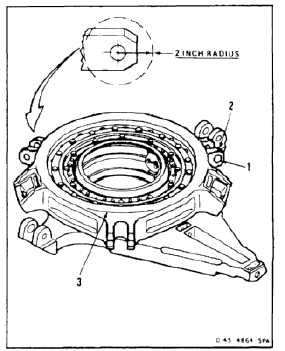

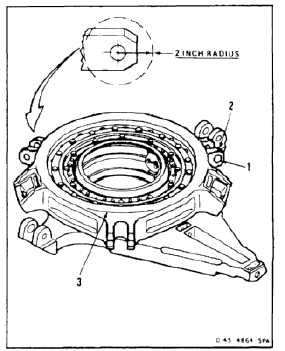

1.

Blend repair damage 0.005 inch to 0.020 inch

in depth within 2 inches of hole center (1) in lugs

(2). Blend smooth. Use abrasive paper (E10).

Rework shall not exceed 0.020 inch in depth.

2.

Check thickness of lugs (2) after rework. Lug

thickness shall not be less than 0.750 inch.

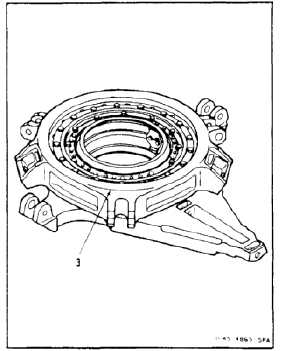

3.

Blend repair damage 0.010 inch to 0.020 inch in

depth in all other areas of rotating ring (3). Blend

smooth. Use abrasive paper (E10). Rework shall

not exceed 0.020 inch in depth.

INSPECT

Alodine (E65) is an oxidizer. Discard

cloths which contain this material in a

separate container. If discarded with

cloths contaminated with acetone,

MEK, or other organic solvents,

combustion can result. In case of

contact, immediately flush skin or eyes

with water for at least 15 minutes.

Get medical attention for eyes.

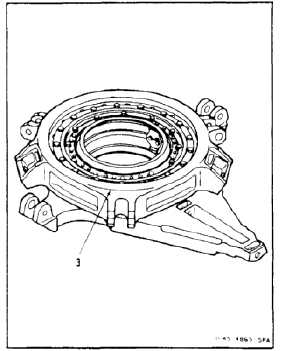

4.

Apply alodine (E65) to repaired area of ring (3).

Wear gloves (E184.1).

5.

Apply one coat of wash primer (E302) to repaired

area of ring (3). Allow primer to dry for 30

minutes. Wear gloves (E184.1).

6.

Apply one coat of epoxy primer (E292.1) to

repaired area of ring (3). Allow primer to dry for

1 hour. Wear gloves (E184.1).

FOLLOW-ON MAINTENANCE:

None

END OF TASK

5-670