TM 55-1520-240-23-4

5-117.1

DISASSEMBLE AND INSPECT FWD AND AFT SWASHPLATE ASSEMBLY

BEARINGS (Continued)

5-117.1

INSPECT BEARING

CAUTION

Replace swashplate assembly if any

of the conditions in step 4 are found.

NOTE

Do not attempt to clean or wipe

the grease from bearing prior to

performing the next step.

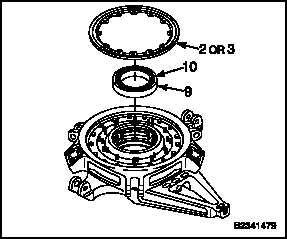

4.

Visually inspect grease for debris and bearing (9)

for damage. Use a flashlight or other suitable

light source. Inspect for orange/red pieces of

debris. The lower grease seal is elastomeric

orange/red in color; therefore this type of rubber

debris may be indicative of damage to the lower

seal. Inspect the bearing ball separator cages

(10) for damage, such as raised, overlapping,

or broken cage segments, or multiple adjacent

uncaged ball bearings.

WARNING

Do not use cloths or rags to clean

the bearing area as this may snag or

catch on the bearing cage.

5.

Using fingers, wipe away excess grease in cavity

and repeat instructions in step 4 above.

CAUTION

Replace grease seal if crack is found.

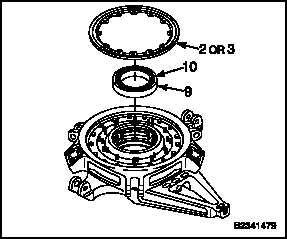

6.

Inspect grease seal (2 or 6) for nicks, scratches,

gouges, distortion, and cracks around bolt/stud

holes.

a.

Blend out minor nicks, scratches, and gouges

with abrasive paper (E14).

b.

Apply alodine (E65) with brush (E86) to

repaired area of grease seal (2 or 6). Wear

gloves (E184.1).

c.

Apply one coat of epoxy primer (E292.1) to

repaired area of grease seal (2 or 6). Allow

primer to dry for 30 minutes. Wear gloves

(E184.1).

5-666.2

Change 1