TM 55-1520-240-23-4

5-87.2

INSPECT SHOCK ABSORBER WITH ELASTOMERIC BEARINGS

(Continued)

5-87.2

NOTE

Evidence of small or dust-like

elastomeric particles breaking away

from the surfaces of the bearing are

not cause for rejection.

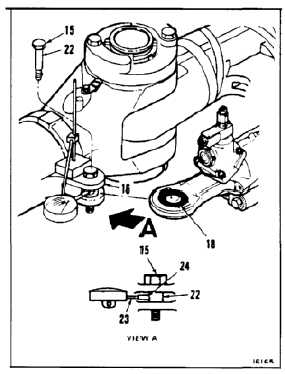

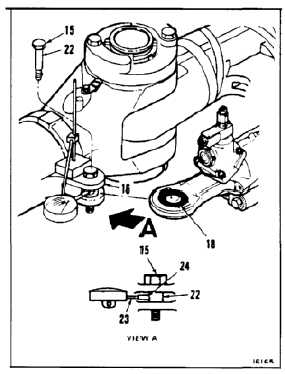

14.

If bearing fails inspection, replace shock absorber

(Task 5-93). Go to step 16.

15.

If bearing is acceptable, reconnect shock

absorber to bracket (16) (Task 5-93).

16.

If the inboard bearing fails inspection, check bolt

(15) for wear. Bolt shank (22) shall be smooth

with no radial wear marks.

17.

Install bolt (15) in bracket (16). Position dial

indicator plunger (23) against bolt shank (22).

Align with bolt axis and use plunger with flat end

(24).

18.

Check bolt (15) movement. Attempt to move bolt

toward, then away from plunger (23). Movement

shall not be more than 0.0015 inch.

19.

Replace bolt if movement is more than 0.0015

inch.

20.

Replace rotor head if after replacing bolt

movement is more than 0.0015 inch (Task 5-9).

21.

Replace rotor head if bushing is loose (Task 5-9).

FOLLOW-ON MAINTENANCE:

Remove tiedown lines from blades (Task 1-26).

Close work platforms (Task 2-2).

END OF TASK

5-531