TM 55-1520-240-23-4

5-87.2

INSPECT SHOCK ABSORBER WITH ELASTOMERIC BEARINGS (Continued)

5-87.2

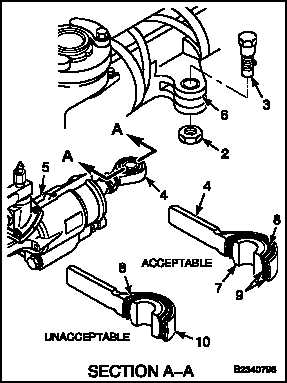

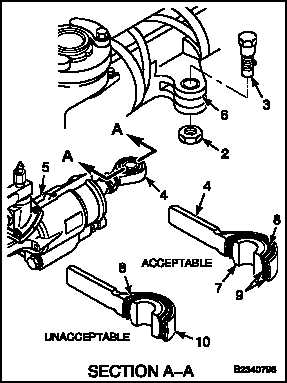

2.

Check for oil leakage. Static leakage at any

location shall not exceed a slight wetting.

Leakage shall be less than one drop. If more,

replace shock absorber (Tasks 5-87 and 5-93).

Perform operational leakage inspection (Task

1-58).

3.

Remove nut (2) and bolt (3) securing shock

absorber (5) to bracket (6) (Task 5-87).

4.

Remove shock absorber rod end bearing (4)

from bracket (6). It may be helpful to have helper

push on trailing edge of the affected blade to

extract rod end from bracket (6).

NOTE

The elastomeric bearing is bonded

to the shock absorber outboard rod

end. If the bearing is found to be

unacceptable, replace the entire rod

end.

5.

Inspect the elastomeric rod end bearing (4) as

follows:

a.

Try to rotate ball (7) by hand. If the ball

rotates, it indicates complete unbonding.

Reject the bearing.

NOTE

If shim is covered by elastomeric

material, the bearing is acceptable.

Evidence of dust-like particles of

elastomeric material or evidence of

small particles breaking away from

the surface of the elastomeric material

are not causes for rejection.

b.

Check if shim (8) is visible. If it protrudes

above elastomeric material (9), reject the

bearing if any of the following conditions exist:

(1)

Protrusion of shim above plane of bearing

housing (10).

(2)

Unbonding of shim from elastomeric

material.

NOTE

On certain bearings, shims are

installed in two pieces. A split

between the shim halves is normal.

(3)

Broken shim. Check with a feeler gauge

or similar tool.

6.

Replace rod end if found unacceptable (Tasks

5-88 and 5-89) and adjust rod end length (Task

5-90). Go to step 8.

7.

If bearing is acceptable, reconnect rod end to

blade. Go to step 12.

Change 2

5-529