TM 55-1520-240-23-4

5-88.2

INSTALL SHOCK ABSORBER ROD END BEARING (AVIM)

(Continued)

5-88.2

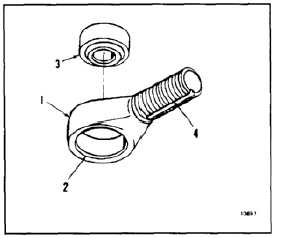

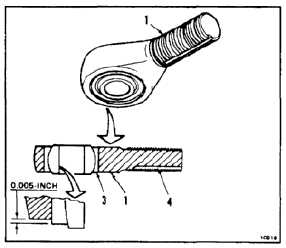

1.

Wipe rod end (1) clean. Use cloth (E120) damp

with solvent (E162). Wear gloves (E186).

2.

Check rod end bore (2). Diameter shall be

1.7485 to 1.7489 inches.

3.

Cool bearing (3) completely in mixture of dry ice

(E92) and methanol (E243). Wear gloves (E187).

4.

Position rod end (1) with groove (4) down.

Do not press bearing on any surface

but outer race. Bearing damage will

result.

5.

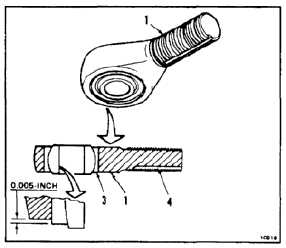

Press bearing (3) into rod end (1). Use

arbor press and pusher (APP E-41) (TM

55-1500-322-24).

6.

Check that bearing (3) is flush with rod end (1),

within 0.005 inch, on same side as groove (4).

Do not stake bearing. Staking marks

cause failure of rod end. This results

in injury to personnel and damage to

equipment.

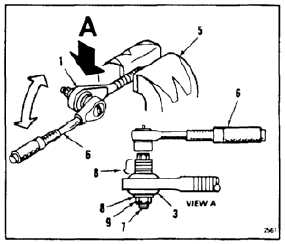

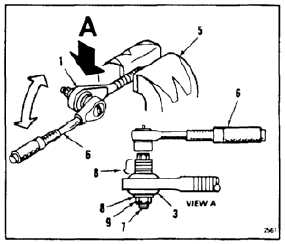

7.

Check torque needed to rotate bearing (3) as

follows:

a.

Clamp rod end (1) in soft jaw vise (5).

b.

Install torque wrench (6) on bearing (3).

Use bolt (7), washers (8), and nut (9). Use

enough washers to keep wrench away from

rod end (1) so wrench can be pulled.

c.

Rotate torque wrench (6). Check torque.

Torque shall be 10 to 60 inch-pounds.

8.

Remove rod end (1) from vise (5).

FOLLOW-ON MAINTENANCE:

None

END OF TASK

5-536