TM 55-1520-240-23-4

5-87.2

INSPECT SHOCK ABSORBER WITH ELASTOMERIC BEARINGS (Continued)

5-87.2

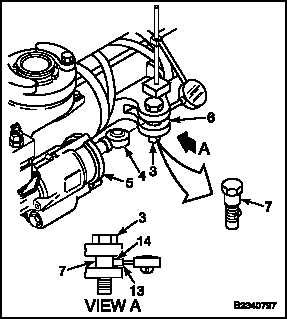

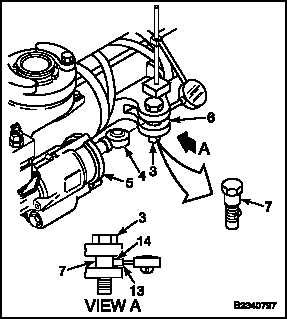

8.

With shock absorber rod end (4) free of bracket

(6), check bolt (3) for wear. Bolt shank (7) shall

be smooth with no wear. Measure diameter of

bushing at several places. Use a micrometer.

Minimum diameter of bushing shall be 1.090

inch.

9.

Install bolt (3) in bracket (6). Position indicator

plunger (13) against bolt shank (7). Align with

bolt axis. Use plunger with flat end (14).

10.

Check bolt (3) movement. Attempt to move bolt

toward, then away from plunger (13). Movement

shall not be more than 0.0015 inch.

11.

Replace bolt (3) and/or bushings in bracket (6)

if excessive play is detected, and reinstall shock

absorber.

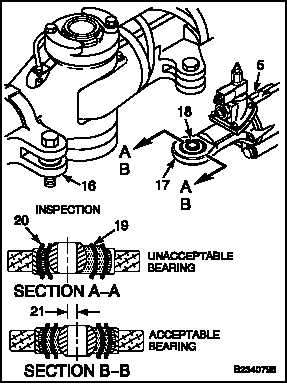

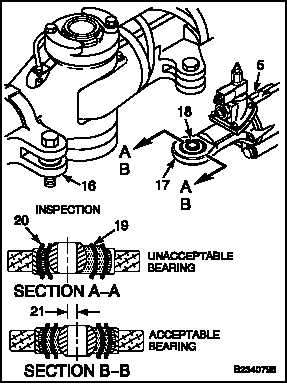

12.

Disconnect shock absorber (5) at inboard bracket

(16) (Task 5-87). It may be helpful to have helper

push on trailing edge of blade to help extract

shock absorber (5) from bracket (16).

13.

Inspect the elastomeric bearing (18) and reject it

if any of the following conditions exist:

a.

Evidence of shim displacement on distortion

(19) with raising of elastomer (20).

b.

Permanent offset (21) of inner bushing.

c.

Loss of elastomer material exceeding 20

percent of the bearing thickness.

d.

Separation of inner race and elastomeric

(inner race turns by hand with elastomeric).

5-530