TM 55-1520-240-23-4

5-87.1

INSPECT SHOCK ABSORBER WITH TEFLON BEARINGS

(Continued)

5-87.1

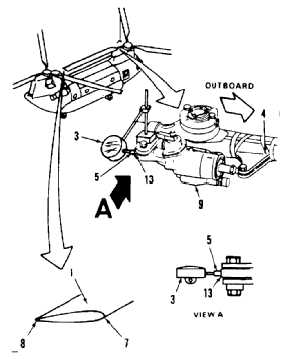

12.

Connect shock absorber (9) at bracket (4) (Task

5-93).

13.

Mount indicator (3) on inboard lug (10). Position

indicator plunger (5) against inboard end (13) of

absorber (9), at midstroke of plunger. Align with

absorber axis.

14.

Record indicator (3) reading.

15.

Have helper apply force to tip of blade (1) at

leading edge (7). Blade should just move.

Record indicator (3) reading C.

16.

Have helper apply force to tip of blade (1) at

trailing edge (8). Blade should just move. Record

indicator reading D.

17.

Subtract reading D of step 16 from reading C of

step 15. Result must not be more than 0.010

inch. If not more, go to step 23. If more, perform

steps 18 thru 22, then go to step 23.

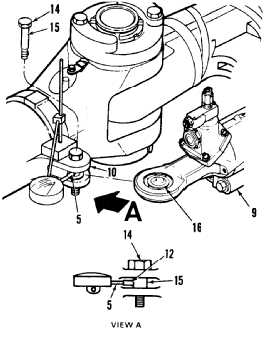

18.

Disconnect absorber (9) at unboard lug (10)

(Task 5-87).

19.

Check bolt (14) for wear. Bolt shank (15) shall be

smooth, with no radial wear marks.

20.

Install bolt (14) in lug (10). Position indicator

plunger (5) against bolt shank (15). Align with

bolt axis. Use plunger with flat end (12).

21.

Check bolt (14) movement. Attempt to move bolt

toward, then away from plunger (5). Movement

shall not be more than 0.0015 inch.

22.

If results from steps 19 and 21 are not cause

of excess movement, replace absorber inboard

bearing (16) (Task 5-89.2).

23.

Connect shock absorber (9) at inboard lug (10)

(Task 5-93).

FOLLOW-ON MAINTENANCE:

Remove tiedown lines from blades (Task 1-26).

Close work platforms (Task 2-2).

END OF TASK

5-527