TM 55-1520-240-23-3

4-75

INSTALL ENGINE AIR INLET FAIRING

(Continued)

4-75

NOTE

Engine access cover is not shown for

clarity.

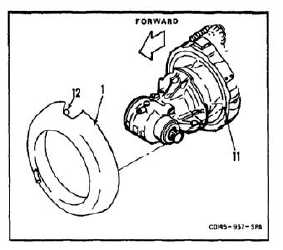

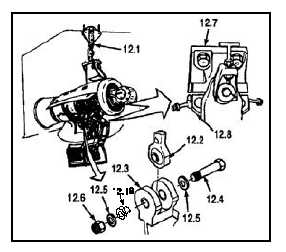

3.

Position fairing (1) on engine (11) so locating pin

(12) aligns with engine.

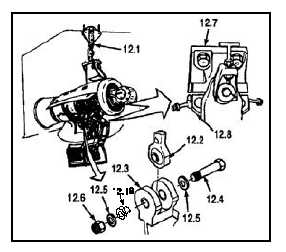

3.1.

Slowly lower hoist (12.1) until lower end of aft

engine mount link (12.2) aligns with mount (12.3).

Install bolt (12.4), washers (12.5), and nut (12.6).

Torque nut (12.6) to 350 to 400 inch-pounds to

seat bushing (12.18). Loosen nut and retorque

nut to 20 inch-pounds above run-on torque

value, but in no case should the torque be less

that 70 inch-pounds.

4.

Continue to lower hoist (12.1) slowly until forward

adapters (12.7) rest on caps (12.8).

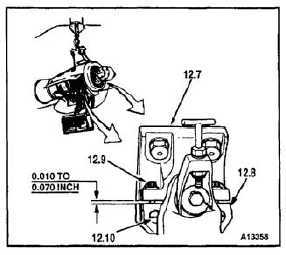

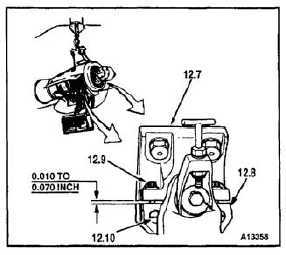

5.

Check that friction torque of bolts (12.9) in barrel

nuts (12.10) is not less than 7 inch-pounds.

5.1.

Push four bolts (12.9) up and over adapter (12.7).

5.2.

Torque bolts (12.9) to 105 inch-pounds. Check

that gap between adapters (12.7) and caps

(12.8) is 0.010 to 0.070 inch.

5.3.

If gap measurement exceeds 0.010 to 0.070

inch, repair mount (Task 4-32), and repeat step

5.2.

5.4.

Check bolts (12.9). Bolt threads shall protrude

a minimum of two threads through barrel nuts

(12.10), but shall not bottom out. Add washers

under bolthead if bolt is bottoming out. Lockwire

bolts. Use lockwire (E231).

INSPECT

4-321