TM 55-1520-240-23-9

11-92

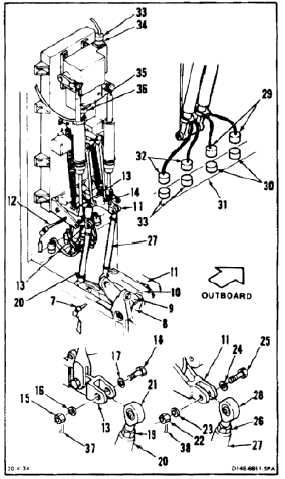

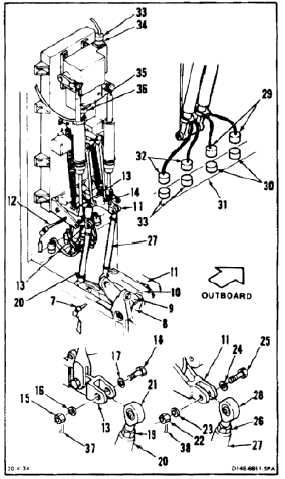

INSTALL CONTROL PALLET STA 120

(Continued)

11-92

3.

Install transfer bellcrank rig pin (T128) (7) through

four bellcranks (8, 9,10, and 11).

4.

Install pitch and roll rig pin (T134) (12) through

two bellcranks (13 and 14).

5.

Remove nut (15), two washers (16 and 17), and

bolt (18) from bellcrank (13).

6.

Loosen nut (19) of link (20). Turn rod end (21)

until link can be positioned in bellcrank (13) with

bolt installed loosely.

7.

Install bolt (18), two washers (17 and 16) and

nut (15) in bellcrank (13). Do not torque nut at

this time.

8.

Remove nut (22), two washers (23 and 24) and

bolt (25) from bellcrank (11).

9.

Loosen nut (26) of link (27). Turn rod end (28)

until link can be positioned in bellcrank (11) with

bolt (25) installed loosely.

10.

Install bolt (25), two washers (24 and 23) and

nut (22) in bellcrank (11). Do not torque nut at

this time.

11.

Connect two roll LVDT connectors (29) to

receptacles (30) on structure (31). Remove tag.

12.

Connect two pitch LVDT connectors (32) to

receptacles (33) on structure (31). Remove tag.

13.

Connect connector (33) to pitch CCDA (34).

Remove tag.

14.

Connect connector (35) to roll magnetic brake

(36). Remove tag.

15.

Torque two nuts (19 and 26) to 103 inch-pounds.

16.

Torque two nuts (15 and 22) to 30 to 45

inch-pounds. Install two cotter pins (37 and 38).

17.

Check two bolts (18 and 25). Bolts shall not

rotate with torque less than 10 inch-pounds.

There shall be no axial looseness, if bolts rotate

or are loose, add washer under nuts and repeat

step 16.

18.

Remove pin (12) from bellcranks (13 and 14).

19.

Remove pin (7) from bellcranks (8, 9, 10, and 11).

INSPECT

FOLLOW-ON MAINTENANCE:

Install roll, yaw, and thrust connecting links (Task

11-106).

Install DASH actuator (Task 11-164).

Remove servocylinder safety blocks (T31) (Task

11-29).

Perform operational check of flight controls (TM

55-1520-240-T).

Close closet backup panel (Task 2-2).

Install closet acoustic blanket (Task 2-108).

END OF TASK

11-492