TM 55-1520-240-23-9

11-77

ASSEMBLE PILOT’S COCKPIT CONTROL ASSEMBLY

(Continued)

11-77

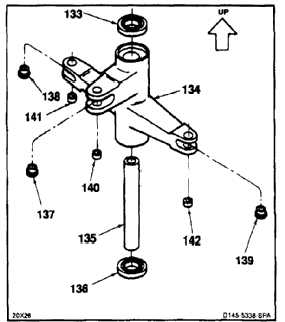

ASSEMBLE YAW BELLCRANK

75.

Press bearing (dissimilar metals) (133) in

bellcrank (134) until it bottoms. Use arbor press.

76.

Install spacer (dissimilar metals) (135) in

bellcrank (134). Press bearing (dissimilar metals)

(136) in bellcrank until it bottoms. Use arbor

press.

77.

Install three bushings (dissimilar metals) (137,

138, and 139), flange inward, in upper lugs of

bellcrank (134).

78.

Install three bushings (dissimilar metals) (140,

141, and 142) in lower lugs of bellcrank (134).

INSPECT

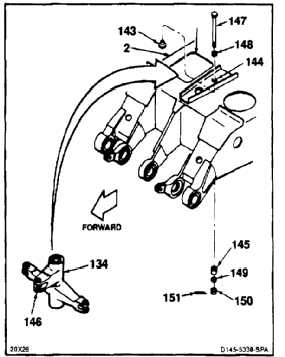

INSTALL YAW BELLCRANK

79.

Install bushing (dissimilar metals) (143), flange

inward, in hole (144) of support (2).

80.

Install bushing (dissimilar metals) (145) opposite

hole (144) in support (2).

FLIGHT SAFETY PARTS

This is an installation critical flight

safety part. All aspects of its assembly

and installation must be ensured at

each joint connection and mounting to

the airframe.

Ensure that all bushings are properly

installed (including orientation) in

the output and input clevises of the

bellcrank assembly.

Ensure bellcrank hub bearings are

serviceable and properly installed.

Ensure associated bushings are

properly installed in the adjacent

control box assembly.

Ensure proper attaching hardware

(impedance type bolt, nut, and

washers) is installed including

verification of bolt head orientation,

torque, and installation of cotter pins.

Loose attachments within flight control

primary linkage will degrade aircraft

control. Missing components will

cause loss of control.

81.

Install bellcrank (134) in support (2) with arm

(146) up and forward. Remove tag.

82.

Install bolt (147), two washers (148 and 149) and

nut (150) in support (2) and bellcrank (134).

83.

Torque nut (150) to 60 to 90 inch-pounds.

Install cotter pin (151).

84.

Check bolt (147) not shall not rotate with torque

less than 10 inch-pounds. There shall be no

axial looseness. If bolt rotates or is loose, add

washer under nut and repeat step 83.

INSPECT

11-369