TM 55-1520-240-23-9

11-77

ASSEMBLE PILOT’S COCKPIT CONTROL ASSEMBLY

(Continued)

11-77

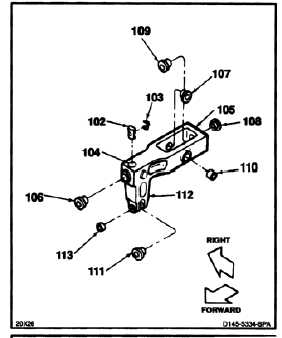

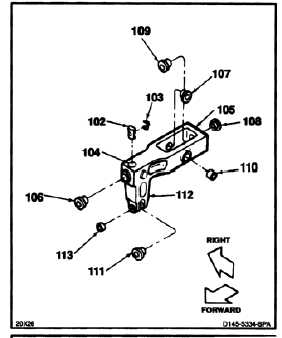

ASSEMBLE ROLL INPUT BELLCRANK

55.

Position nut (102) in retainer (103), flat side to

retainer.

56.

Install nut (102) and retainer (103) in hole (104)

of bellcrank (105), nut forward.

57.

Install bushing (dissimilar metals) (106) in

forward end of bellcrank (105).

58.

Install two bushings (dissimilar metals) (107 and

108) in aft end of bellcrank (105).

59.

Install bushing (dissimilar metals) (109) flange

inward, in right side of bellcrank (105).

60.

Install bushing (dissimilar metals) (110) in left

side of bellcrank (105).

61.

Install bushing (dissimilar metals) (111) flange

inward, in aft lug of arm (112).

62.

Install bushing (dissimilar metals) (113) in

forward lug of arm (112).

INSPECT

INSTALL ROLL INPUT BELLCRANK

FLIGHT SAFETY PARTS

This is an installation critical flight

safety part. All aspects of its assembly

and installation must be ensured at

each joint connection and mounting to

the airframe.

Ensure that all bushings are properly

installed (including orientation) at the

following locations: at the output clevis

of the bellcrank, at both the forward

and aft ends along the roll pivot axis,

and on both sides at the pivot axis of

the mating socket assembly.

Ensure proper barrel nut and retainer

are installed in cavity at forward end

of the bellcrank.

Ensure proper attaching hardware

(impedance type bolt, nut, and

washers) is installed including

verification of bolt head orientation,

torque, and installation of cotter pins.

Loose attachments within flight control

primary linkage will degrade aircraft

control. Missing components will

cause loss of control.

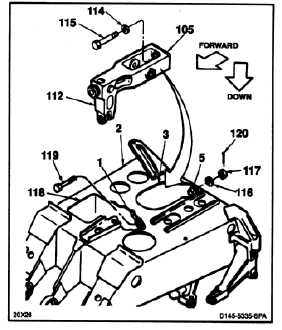

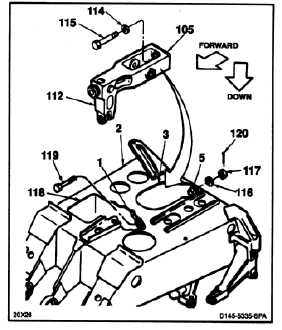

63.

Working through access (3), position bellcrank

(105) in support (2), arm (112) down and forward.

64.

Install washer (114) and bolt (115) through aft

end of bellcrank (105) and bearing (5).

65.

Install washer (116) and nut (117) on bolt (115).

Do not tighten nut at this time.

66.

Working through access (118), slide bolt (119)

through bearing (1) and install in bellcrank (105).

Torque bolt to 75 inch-pounds.

67.

Torque nut (117) to 60 to 90 inch-pounds.

Install cotter pin (120).

11-367