TM 55-1520-240-23-9

11-52

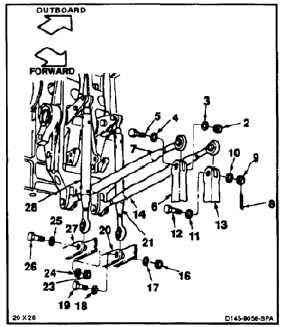

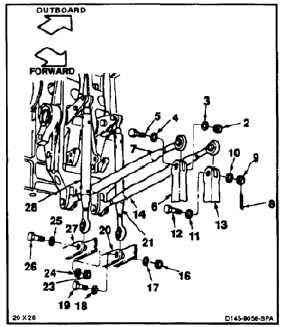

ADJUST FIRST AND SECOND STAGE BELLCRANK CUMULATIVE STOPS

(Continued)

11-52

Bushings must be in bellcranks before

installing bolts; otherwise, damage to

components will result.

NOTE

Impedance bolts are installed in flight

control connections. These bolts are

self-retaining and require a special

nut and torque (Task 1-13).

22.

Untie and position link (28) in bellcrank (27).

Install bolt (26), two washers (25 and 24) and nut

(23). Do not torque nut at this time.

23.

Untie and position link (21) in bellcrank (20).

Install bolt (19), two washers (18 and 17), and

nut (16). Do not torque nut at this time.

24.

Untie and position link (14) in bellcrank (13).

Install bolt (12), two washers (11 and 10), and

nut (9). Do not torque nut at this time.

25.

Untie and position link (7) in bellcrank (6). Install

bolt (5), two washers (4 and 3), and nut (2). Do

not torque nut at this time.

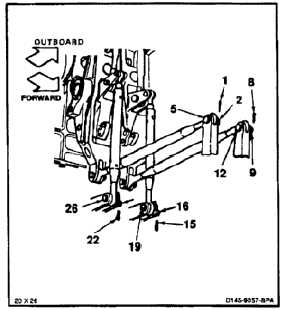

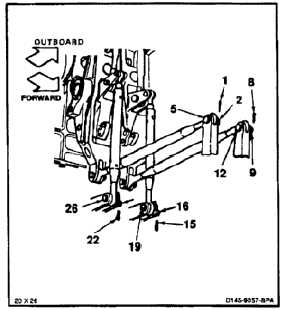

26.

Torque four nuts (2, 9, 16, and 23) to 30 to 45

inch-pounds. Install four cotter pins (1, 8, 15,

and 22). Check four bolts (5, 12, 19, and 26).

Bolts shall not rotate with torque less than 10

inch-pounds. There shall be no axial looseness.

If bolt rotates or is loose, add washer under nut

and repeat step 26.

FOLLOW-ON MAINTENANCE:

Connect forward and aft servocylinder connecting

links (Task 11-193).

Remove servocylinder safety blocks (T31) (Task

11-29).

Perform operational check of flight control system

(TM 55-1520-240-T).

Install forward transmission drip pan (Task 2-3).

Install closet backup panel (Task 2-2).

Install closet acoustic blanket (Task 2-108).

Close forward left work platform (Task 2-2).

END OF TASK

11-228