TM 55-1520-240-23-9

11-52.1

ADJUST FIRST AND SECOND-STAGE BELLCRANK THRUST UP INBOARD AND YAW

RIGHT OUTBOARD STOPS

(Continued)

11-52.1

Do not stand, kick, or induce lateral

loads to the thrust idler. A cracked

arm will cause in-flight failure resulting

in disconnecting the thrust cockpit

driver actuator (CCDA) and the

droop eliminator potentiometers

(Without 74 ) or thrust control position

transducer (With 74 ).

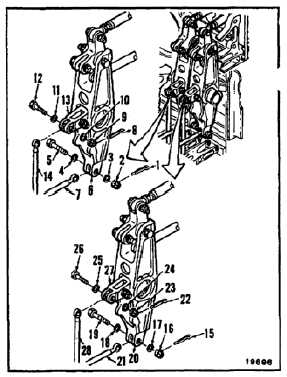

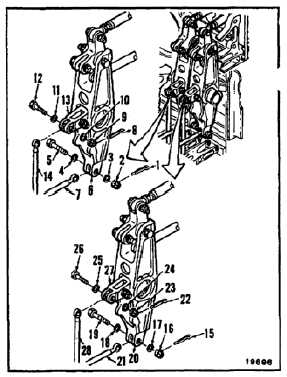

1.

Working in passageway, remove cotter pin (1),

nut (2), two washers (3 and 4), and bolt (5) from

bellcrank (6). Disconnect link (7) from bellcrank.

Tie link away from bellcrank. Use twine (E433).

2.

Remove cotter pin (8), nut (9), two washers

(10 and 11), and bolt (12) from bellcrank (13).

Disconnect link (14) from bellcrank. Tie link away

from bellcrank. Use twine (E433).

3.

Remove cotter pin (15), nut (16), two washers

(17 and 18), and bolt (19) from bellcrank (20).

Disconnect link (21) from bellcrank. Tie link away

from bellcrank. Use twine (E433).

4.

Remove cotter pin (22), nut (23), two washers

(24 and 25), and bolt (26) from bellcrank (27).

Disconnect link (28) from bellcrank. Tie link away

from bellcrank. Use twine (E433).

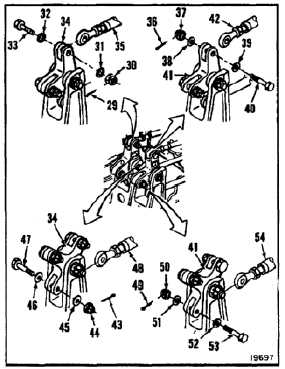

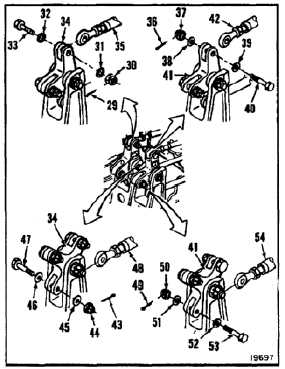

5.

Have helper working from forward left work

platform, remove cotter pin (29), nut (30), two

washers (31 and 32), and bolt (33) from bellcrank

(34). Disconnect link (35) from bellcrank. Tie link

away from bellcrank. Use twine (E433).

6.

Remove cotter pin (36), nut (37), two washers

(38 and 39), and bolt (40) from bellcrank (41).

Disconnect link (42) from bellcrank. Tie link away

from bellcrank. Use twine (E433).

7.

Remove cotter pin (43), nut (44), two washers

(45 and 46), and bolt (47) from bellcrank (34).

Disconnect link (48) from bellcrank. Tie link away

from bellcrank. Use twine (E433).

8.

Remove cotter pin (49), nut (50), two washers

(51 and 52), and bolt (53) from bellcrank (41).

Disconnect link (54) from bellcrank. Tie link away

from bellcrank. Use twine (E433).

11-230