TM 55-1520-240-23-6

7-214

DISASSEMBLE AND INSPECT UTILITY RESERVOIR/COOLER (AVIM)

(Continued)

7-214

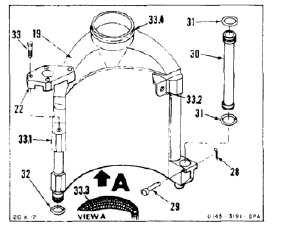

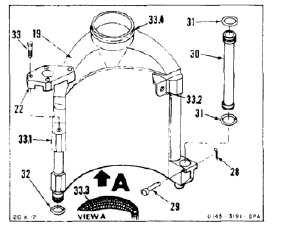

14.

Remove cotter pin (28), pin (29), and return tube

(30) from cooler (19). Use 7/16 inch deep well

socket.

15.

Remove two packings (31) from tube (30).

Inspect tube. (Refer to steps 5.1 and 5.2.)

16.

Remove packing (32) from cooler (19).

17.

Drain fluid from cooler (19). Use container for

fluid. Use cloths (E120) to clean up spills.

18.

Remove bolt (33) and bracket (22) from cooler

(19).

18.1.

Check mounting flanges (33.1 and 31.2) of cooler

(19). Flanges shall not be bent.

18.2.

Check welds on cooler (19) for cracks. There

shall be no cracks. If a crack is suspected, refer

to TM 1-1520-253-23.

18.3.

Check fins (33.3) at bottom of cooler (19).

Straighten bent fins.

Heat will damage cooler.

18.4.

Check neck (33.4) of cooler (19) for cracks and

distortion. There shall be no cracks. Smooth

distorted neck back to original shape. Do not

apply heat. If a crack is suspected, refer to TM

1-1520-253-23.

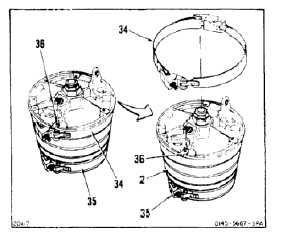

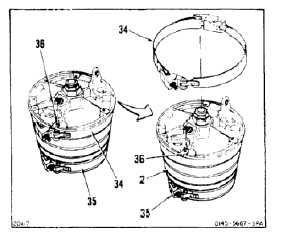

18.5.

Check strap mounts (34 and 35). There shall

be no cracks or kinks. There shall be no broken

welds. If a crack is suspected, refer to TM

1-1520-253-23.

19.

If strap mount (34 or 35) is damaged, remove

as follows:

a.

Loosen one side of strap mount (34 or 35)

enough to clear timing clamp 36).

b.

Lift strap mount (34 or 35) to clear timing

clamp (36). Remove strap mount from

reservoir (2).

20.

Check reservoir (2) for condition. There shall be

no cracks or dents. If a crack is suspected, refer

to TM 1-1520-253-23.

FOLLOW-ON MAINTENANCE:

None

END OF TASK

7-814