TM 55-1520-240-23-9

11-217

INSTALL FORWARD LCT YOKE

(Continued)

11-217

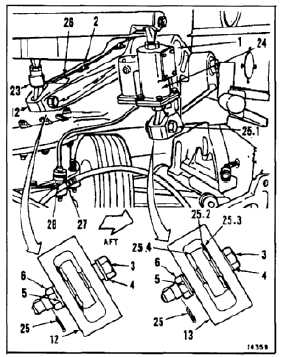

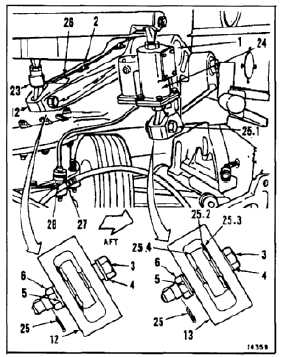

12.

Raise yoke (1). Guide connecting link (23) into

lug (12) and actuator (24) into lug (13).

13.

Install recessed washers (4) on bolts (3), recess

toward head. Install bolts (3) dry, heads aft,

washers (5), and nuts (6).

14.

Torque nuts (6) to 290 to 660 inch-pounds.

Install cotter pins (25). An additional AN960-816L

washer may be used to align cotter pin.

Some clearance is required to ensure

that the LCT actuator lower end fitting

(25.4) is not clamped against the face

of the bushing flange (25.3).

14.1.

Check that actuator swivels at lower end-fitting

bearing (25.1). Any measurable clearance

between the actuator anti-rotation lugs (25.2)

and the bushing flange (25.3) on the yoke is

acceptable. If there is no clearance, add a thin

washer between the bearing inner race and the

flange bushing.

15.

Attach connecting link cable (26) to five mounting

plates (2) on yoke (1). Use cable straps (E375).

16.

Connect actuator connector (27) to receptacle

(28).

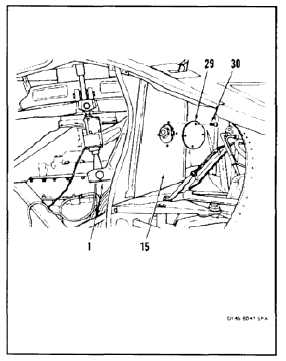

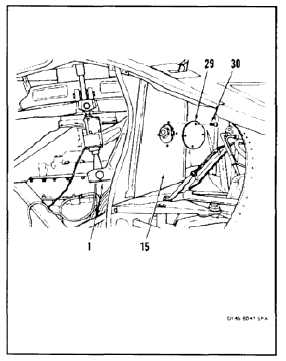

17.

Install access plate (29) and four screws (30) in

bulkhead (15) aft of yoke (1).

FOLLOW-ON MAINTENANCE:

Connect forward rotor pitch links (Task 5-99).

Remove servocylinder safety blocks (T31) (Task

11-29).

Perform flight controls operational check (TM

55-1520-240-T).

Close forward pylon work platforms (Task 2-2).

END OF TASK

11-859