TM 55-1520-240-23-9

11-7

INSPECT FLIGHT CONTROL SYSTEM ALUMINUM AND STEEL CONNECTING

LINKS

(Continued)

11-7

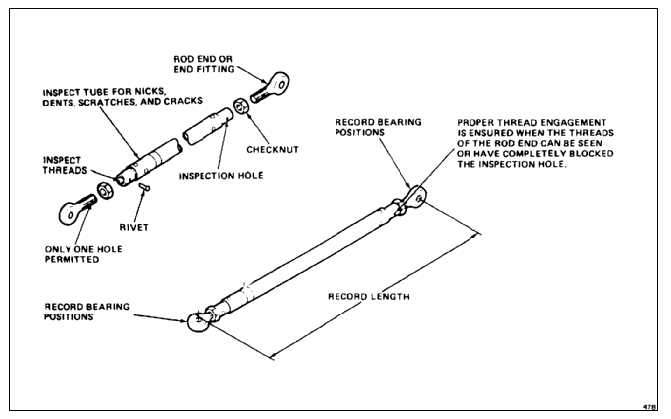

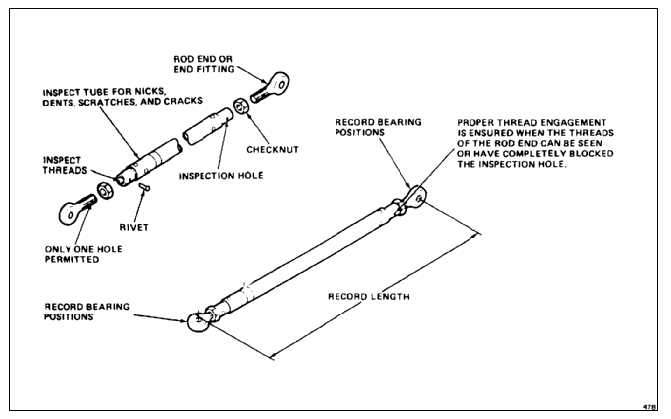

ADJUSTABLE CONNECTING LINKS

NOTE

Adjustable connecting links are made

of round seamless aluminum alloy

2024-T4 or steel tubing 4130. Rod

end fittings are swaged or riveted on

each end.

6.

Inspect links for cracks. There shall be no

cracks. If a crack is suspected, refer to TM

1-1520-253-23.

7.

Inspect links for nicks and scratches. Blend out

(Task 11-14).

8.

Check that blended area is large enough to blend

smoothly with next undamaged area.

NOTE

These limits apply to out-of-round

damage and dents, except for tubes

over 2 inches diameter, which

must not be more than 0.015 inch

out-of-round.

9.

Check link for dents. Replace link if following

limits are exceeded:

a.

Divide tube into three equal lengths.

b.

Check for dents in middle one third of tube.

One dent is allowed. Depth of dent must not

be more than 0.010 inch. Dent must be free

of nicks and scratches.

c.

Check for dents in outer thirds of tubes. Total

of two dents is allowed. Depth of dent must

not be more than 0.015 inch. Dent must be

free of nicks and scratches.

10.

Check link for out-of-round. Replace link if

following limits are exceeded:

a.

For tubes less than 2 inches diameter,

out-of-round must not be more than 0.010

inch in middle one third of tube.

b.

For tube larger than 2 inches diameter,

out-of-round must not be more than 0.015

inch in middle one third of tube.

c.

For any diameter tube, out-of-round must

not be more than 0.015 inch in outer third

sections of tubes.

11-37