TM 55-1520-240-23-9

11-9

INSPECT BELLCRANK AND CONNECTING LINK BEARINGS (INSTALLED)

11-9

INITIAL SETUP

Applicable Configurations:

All

Tools:

As Required

Materials:

Wire (E233)

Insulation Sleeving (E204)

Personnel Required:

Medium Helicopter Repairer

Inspector

References:

TM 1-1500-204-23

TM 55-1500-322-24

Task 11-8

Equipment Condition:

Battery Disconnected (Task 1-39)

Electrical Power Off

Hydraulic Power Off

Servocylinder Safety Blocks (T31) Installed (Task

11-28)

Servocylinder Connecting Links Disconnected (Task

11-192)

Access Door Open (As Required) (Task 2-2)

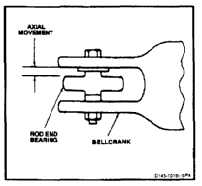

ANTIFRICTION TYPE BEARINGS

1.

Check antifriction type rod end bearing as

follows:

a.

Stop bellcrank from moving. Use wire (E233)

covered with vinyl tubing (E204) or wood

blocks.

b.

Pull then push bearing radially. If looseness

is more than 0.004 inch, remove link and

perform Task 11-8.

NOTE

Rolling element bearings are located

in the flight control closet area, 1st

and 2nd stage mixing units, forward

pylon, tunnel area, aft fuselage, aft

pylon and pedal box area only.

c.

Where there is evidence of an unserviceable

bearing, disconnect sufficient parts of the

system as required so that the individual

bearings may be examined by hand rotation.

Serviceable condition, well-lubricated

bearings feel smooth with no perceptible

roughness, catching or binding. No excessive

external corrosion or worn plating should

be evident on the bearing exterior, and

shields and seals should be undamaged and

operable.

11-42