TM 55-1520-240-23-9

11-7

INSPECT FLIGHT CONTROL SYSTEM ALUMINUM AND STEEL CONNECTING LINKS

11-7

INITIAL SETUP

Applicable Configurations:

Without 38

Tools:

As Required

Materials:

As Required

Personnel Required:

Medium Helicopter Repairer

Inspector

References:

Task 11-8

TM 1-1520-253-23

Equipment Condition:

As Required

FIXED (NON-ADJUSTABLE) CONNECTING LINKS

NOTE

Fixed connecting links are made from

aluminum and steel forgings with

bearings pressed and staked in each

end.

1.

Inspect link for nicks and scratches.

2.

Inspect blending. Depth of blending over entire

link must not be more than 10 percent of material

thickness or 0.004 inch, whichever is less.

2.1.

Inspect link for cracks. There shall be no

cracks. If a crack is suspected, refer to TM

1-1520-253-23.

3.

Check for bearing looseness (Task 11-8).

After APU shutdown and removal

of hydraulic power, inspect link for

bending. Bending can cause a flight

hazard, resulting in personal injury

or death.

4.

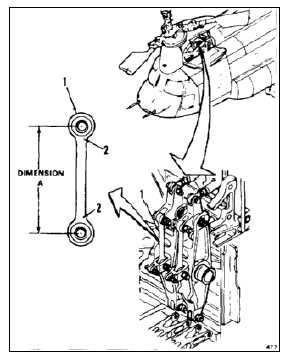

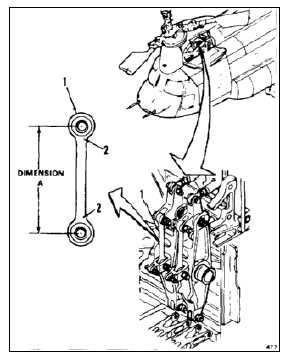

Inspect first stage mixing link (1) for bending in

any direction at narrow section (2), both ends of

link. There shall be no bending.

5.

If bending of link (1) is suspected, remove

link and check center to center dimension A.

Dimension must not be less than 9.714 inches.

11-36