TM 55-1520-240-23-9

11-81

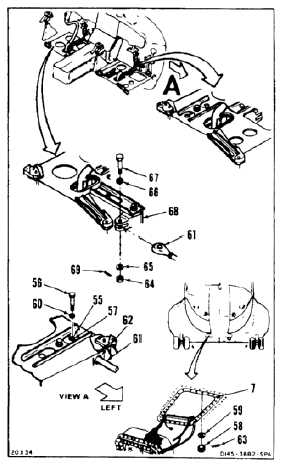

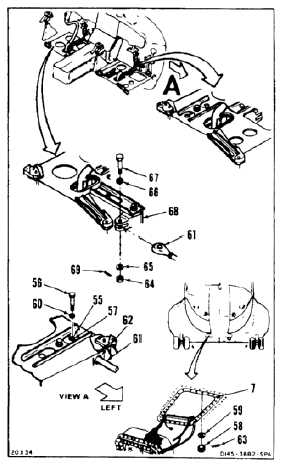

INSTALL PILOT’S COCKPIT CONTROL ASSEMBLY

(Continued)

11-81

INSTALL ROLL CONNECTING LINK

32.

Position bellcrank (55) to align bolt (56) and hole

(57).

33.

Working through right access (7), remove nut

(58), and washer (59) from bolt (56).

34.

Have helper in cockpit remove bolt (56) and

washer (60).

FLIGHT SAFETY PARTS

This is an installation critical flight

safety part. All aspects of its assembly

and installation must be ensured.

Ensure that both rod end jam nuts are

installed and torqued.

Ensure that the rivet through the fixed

rod end bearing is secure.

At installation of this component,

ensure proper attaching hardware

(impedance type bolt, nut, and

washers) is installed including

verification of bolt head orientation,

torque, and installation of cotter pins.

Loose attachments within flight control

primary linkage will degrade aircraft

control. Missing components will

cause loss of control.

35.

Slide roll connecting link (61) from left, through

hole (62) and position in bellcrank (55).

36.

Check that link (61) is free of electrical wiring.

37.

Have helper install washer (60) and bolt (56) in

bellcrank (55) and hold bolt.

38.

Install washer (59), and nut (58) on bolt (56).

Remove tag from link (61).

39.

Torque nut (58) to 30 to 60 inch-pounds. Install

cotter pin (63).

40.

Working from cockpit, remove nut (64), two

washers (65 and 66), and bolt (67) from bellcrank

(68).

41.

Position link (61) in bellcrank (68).

42.

Install bolt (67), two washers (66 and 65), and

nut (64) in bellcrank (68).

43.

Torque nut (64) to 30 to 60 inch-pounds. Install

cotter pin (69).

44.

Check bolts (56 and 67). Bolts shall not rotate

with torque less than 10 inch-pounds. There

shall be no axial looseness. If bolt rotates or is

loose, add washer under nut and repeat step

39 or 43.

11-424