TM 55-1520-240-23-9

11-51

RIG FIRST AND SECOND STAGE BELLCRANKS

(Continued)

11-51

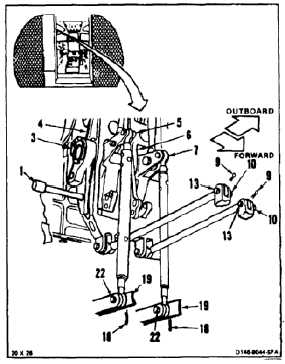

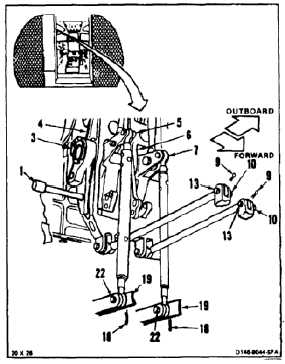

27.

Working from passageway, torque four nuts (10

and 19) to 30 to 45 inch-pounds. Install four

cotter pins (9 and 18).

28.

Check four bolts (13 and 22). Bolts shall not

rotate with torque less than 10 inch-pounds.

There shall be no axial looseness if bolt rotates

or is loose, add washer under nut and repeat

step 24.

29.

Remove pin (1) from bellcranks (7, 6, 5, and 4)

and fitting (3).

INSPECT

FOLLOW-ON MAINTENANCE:

Remove DASH actuator dummy link (Task 11-27).

Install DASH actuator (Task 11-164).

Adjust cumulative stops (Task 11-52).

Remove copilot’s control stick yoke (T125) (Task

11-23).

Remove copilot’s yaw pedal rig pin (T127) (Task

11-23).

Remove copilot’s thrust rig pin (T122) (Task 11-23).

Remove copilot’s rigging fixture (T39) (Task 11-23).

Connect forward and aft servocylinder connecting

links (Task 11-193).

Remove servocylinder safety blocks (T31) (Task

11-29).

Perform operational check of flight control system

(TM 55-1520-240-T).

Install forward transmission drip pan (Task 2-3).

Close forward left work platform (Task 2-2).

Install closet backup panel (Task 2-2).

Install closet acoustic blanket (Task 2-108).

END OF TASK

11-221