TM 55-1520-240-23-6

7-320

FLUSH HOIST CONTROL RETURN TUBING

(Continued)

7-320

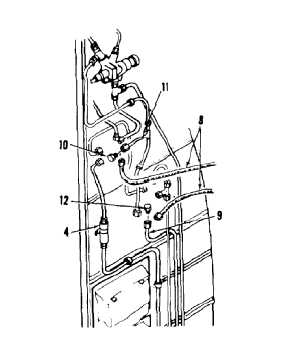

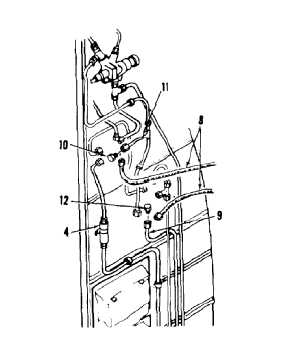

11.

Disconnect hose (8) from tube (9). Use cloths

(E120) and container for spilled fluid. Use gloves

(E186).

12.

Install plug (12) in tube (9).

13.

Remove plug (10) from tube (11).

14.

Connect hose (8) to tube (11).

Do not exceed 500 psi. Otherwise

damage to components can occur.

Keep test stand bypass valve closed.

Otherwise, contaminants could

re-enter the system.

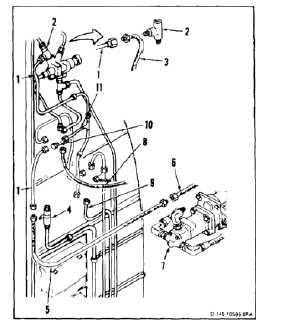

15.

Apply hydraulic power. Set stand to 10 gpm at

500 psi. Flush system for 15 minutes. Check

for leaks.

16.

Remove hydraulic power.

17.

Disconnect hose (5) from tube (1).

18.

Install tube (1) in valve (4).

19.

Disconnect hose (5) from hose (6). Use cloths

(E120) and containers for spilled fluid.

20.

Connect hose (6) to motor (7).

Do not exceed 500 psi. Otherwise

damage to components can occur.

Keep test stand bypass valve closed.

Otherwise, contaminants could

re-enter the system.

21.

Apply hydraulic power. Set stand to 10 gpm at

500 psi. Flush system for 15 minutes. Check

for leaks.

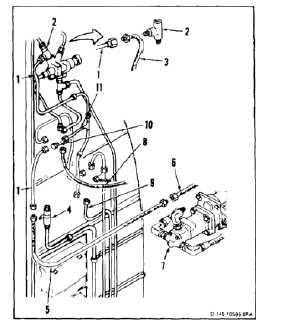

22.

Remove hydraulic power.

23.

Remove plug (12) from tube (9).

24.

Disconnect hose (8) from tube (11). Use cloths

(E120) and container for spilled fluid.

25.

Remove hose (3) from tube (1). Use cloths

(E120) and container for spilled fluid.

26.

Connect tube (1) to tee (2).

INSPECT

7-1151