TM 55-1520-240-23-6

7-269.1

TEST 145HS775 RAMP CONTROL VALVE (AVIM)

(Continued)

7-269.1

NOTE

During all tests, external static seal

leakage shall not exceed a slight

wetting insufficient to form a drop.

Leakage from external dynamic piston

seals shall not exceed 1 drop per 25

cycles of motion.

Unless specified, the following tests

shall be performed with test plug

(T179) installed in place of thermal

relief valve.

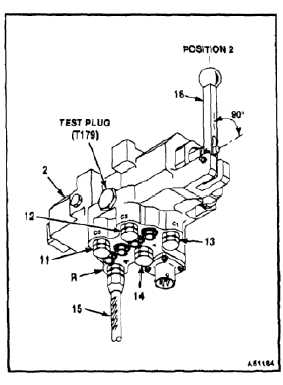

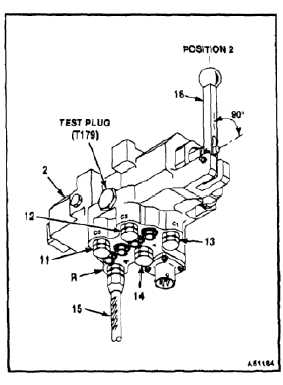

11.

Install pressure caps (11, 12, 13, and 14) on

ports C3, C2, C1, and P of ramp control valve (2).

12.

Connect hydraulic pressure line (15) to return

port R of ramp control valve (2).

13.

Set handle (16) to position 2 (stop) with both

solenoids de-energized, and apply 2515 psig to

pressure line (15) in return port R.

14.

Hold pressure on return port R for 2 minutes

minimum. Check that external leakage is minimal

with no permanent deformation of parts.

15.

Remove pressure and disconnect pressure line

(15) from return port R.

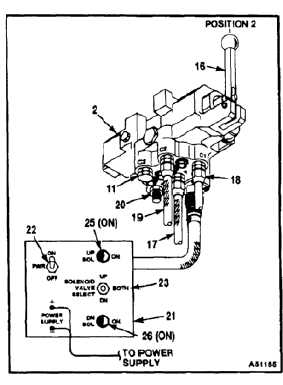

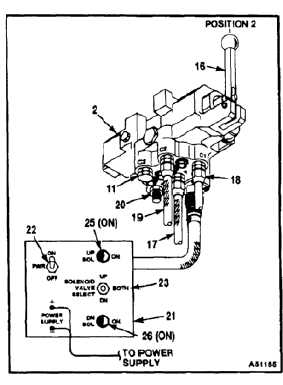

16.

Remove caps (12, 13, and 14) from cylinder

ports C2, and C1, and pressure port P.

17.

Connect pressure lines (17, 18, and 19) to ports

P, C1, and C2. Leave return port R (20) open to

atmosphere and cap (11) on cylinder port C3.

18.

Connect ramp control valve test set (E317) (21)

to ramp control valve (2) and power suppy. Set

power supply to provide 30 vdc.

19.

Set PWR switch (22) to ON, ramp SOLENOID

VALVE SELECT switch (23) to BOTH, and ramp

control valve handle (16) to position 2 (stop).

Both UP and DN SOLENOID lights (25 and 26)

shall come on, indicating power is applied to

both solenoids.

20.

Apply 5025 psig simultaneously to lines (17, 18,

and 19) in ports P, C1, and C2. Ramp control

valve handle (16) shall remain in position 2 (stop).

21.

Hold pressure for 2 minutes. Make sure

external leakage is minimal with no permanent

deformation of parts.

22.

Remove pressure and remove pressure lines (18

and 19) from ports C1 and C2.

7-1001