TM 55-1520-240-23-5

6-32

INSTALL ENGINE DRIVE SHAFT (Continued)

6-32

NOTE

Install left or right engine drive shaft in

same way. Right shaft shown here.

Installation of one-piece and riveted

shafts is similar. Differences are noted

text. Riveted shaft shown here.

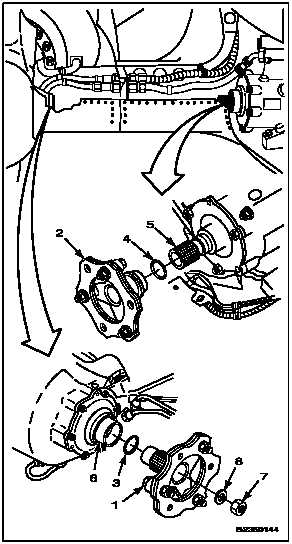

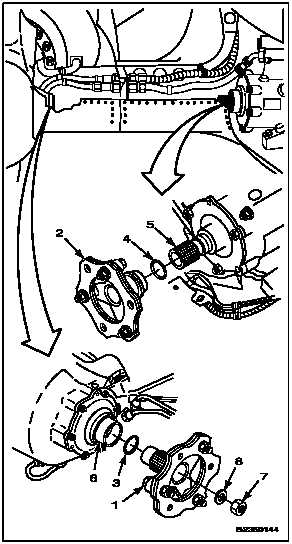

INSTALL ADAPTER ASSEMBLIES

WARNING

Dry cleaning solvent (E162) is

flammable and toxic. It can irritate

skin and cause burns. Use only in

well-ventilated area, away from heat

and open flame. In case of contact,

immediately flush skin or eyes with

plenty of water for at least 15 minutes.

Get medical attention for eyes.

NOTE

On shafts (Without 51 ), shaft and

adapter assemblies are balanced

together and have the same serial

number. If any one is replaced, all

three must be replaced as a unit.

On shafts (With 51 ), shaft and

adapter assemblies may be replaced

individually.

1.

Clean splines of adapter assemblies (1 and

2), combining transmission input shaft (5), and

engine transmission output shaft (6). Use dry

cleaning solvent (E162) and cloths (E120). Wear

gloves (E186). Pack all splines with grease

(E190.1).

2.

Coat packing (4) with grease (E190.1). Install

packing on combining transmission input shaft

(5).

3.

Coat packing (3) with grease (E190.1). Install

packing on adapter assembly (1).

4.

Install adapter assembly (2) on combining

transmission input shaft (5). Wipe off excess

grease with cloths (E120).

5.

Install adapter assembly (1) in engine

transmission output shaft (6). Wipe off excess

grease with cloths (E120).

NOTE

If nut does not meet friction torque,

nut must be replaced.

6.

Coat thread of nut (7) with grease (E190.1).

Wear gloves (E186). Install washer (8) and nut in

adapter assembly (1). Check nut (7) for friction

torque of a least 7 inch-pounds. Torque nut to

120 inch-pounds.

6-103