TM 55-1520-240-23-5

6-31.1

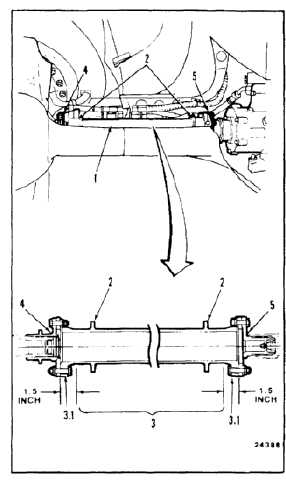

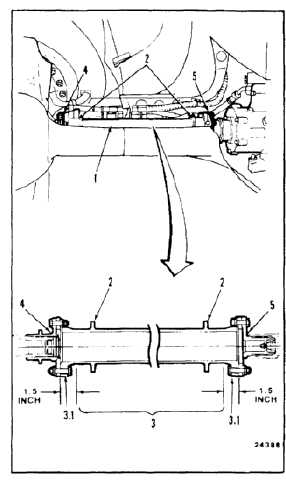

REPAIR ONE-PIECE ENGINE DRIVE SHAFT (INSTALLED)

(Continued)

6-31.1

NOTE

Repair left or right engine drive shaft

in same way. Right shaft shown.

1.

Blend out nicks, scratches, and gouges on center

section (3) of shaft (1), including balance flanges

(2). Use abrasive pads (E2). Do not go deeper

than 0.010 inch. Keep a blend radius of at least

0.5 inch. The blend area shall not exceed 3.14

square-inches (the area of a 2 inch circle).

2.

Blend out nicks, scratches, and gouges on

outside diameter of lugs (3.1). Use emery cloth

(E125). Do not go deeper than 0.025 inch.

3.

Remove nicks, scratches, or gouges on adapters

(4 and 5) by light hand polishing. Use abrasive

pads (E2). Do not go deeper than 0.001 inch.

Replace adapter assemblies if defects cannot be

removed by polishing.

4.

Remove light scratches, corrosion, and nicks

from outside edge and face of plates bolted to

adapters (4 and 5). Use abrasive pads (E2). Do

not go deeper than 0.001 inch.

INSPECT

Epoxy primer (E292 or E293) is

flammable and toxic. Avoid inhaling.

Use only with adequate ventilation,

away from heat or open flame. In

case of contact, immediately flush

skin or eyes with water for at least

15 minutes. Get medical attention

for eyes.

5.

Touch up shaft (1) as needed with two coats of

epoxy primer (E292 or E293). Touch up adapters

(4 and 5) with epoxy primer (E292 or E293) and

epoxy topcoat (E166). Wear gloves (E186).

FOLLOW-ON MAINTENANCE:

Close engine transmission fairing access cover (Task

2-2).

Install engine air inlet screens (Task 4-79).

Install engine drive shaft access cover (Task 2-2).

Close pylon lower fairing (Task 2-2).

Close pylon access doors (Task 2-2).

END OF TASK

6-98