TM 55-1520-240-23-5

6-30.2

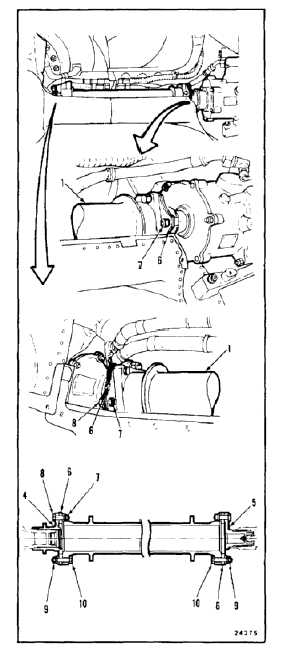

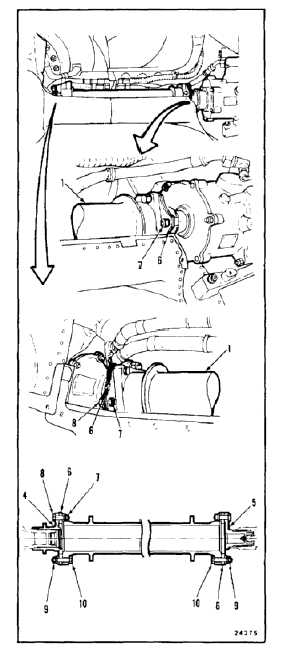

INSPECT ONE-PIECE ENGINE DRIVE SHAFT (INSTALLED)

(Continued)

6-30.2

2.

Inspect adapter areas for damage listed below:

a.

Cracks, nicks, or gouges in visually

accessible areas of plates (6). Use a 3X

to 5X power magnifying glass to check.

Repair light scuffs, nicks, or scratches (Task

6-31.1). Replace adapter assemblies with

cracks, nicks or gouges in plates deeper

than 0.001 inch (Tasks 6-30 and 6-32). If

a crack is suspected in plate, refer to TM

1-1520-253-23.

b.

Nicks on inside edges of plates (6). Use a

pointed scribe to check. If nicks are found,

replace adapter assemblies.

Do not allow bolts to turn. If bolts turn,

the bolts and plates or adapter can be

damaged. Only one bolt may be loose

at a time or you lose balance.

c.

Cracked or loose nuts (7) and bolts (8).

Cracked or loose nuts (9) and bolts (10).

Replace cracked nuts and bolts.

3.

Check torque on nuts (7) at each adapter

assembly (4 and 5). Torque shall be at 440

inch-pounds.

a.

If torque is less than 440 inch-pounds in

more than one location per adapter assembly,

replace the adapter assembly and attaching

hardware (Tasks 6-30 and 6-32).

b.

If torque is less than 440 inch-pounds at

only one location per adapter assembly,

check plates (6) in the area of loose bolt

(8) for cracks. If cracks are found, replace

affected adapter assembly and attaching

hardware (Tasks 6-30 and 6-32). If plates are

acceptable, torque nut to 440 inch-pounds.

c.

If a nut or bolt fails during torquing, replace

the adapter assembly and attaching hardware

(Tasks 6-30 and 6-32).

6-89