TM 55-1520-240-23-5

6-30.3

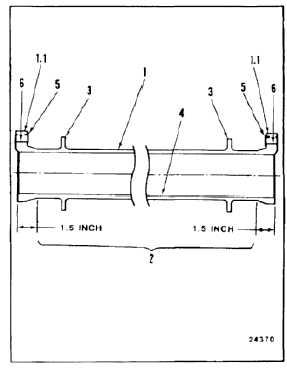

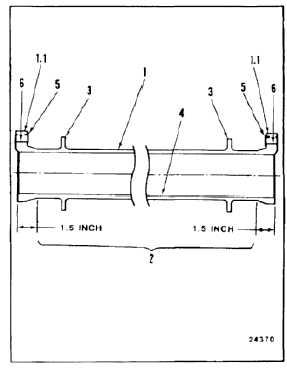

INSPECT ONE-PIECE ENGINE DRIVE SHAFT (REMOVED)

(Continued)

6-30.3

NOTE

Inspect left or right drive shaft in same

way.

Shaft and adapter assemblies are

balanced separately. If any one

is damaged, it may be replaced

individually.

1.

Inspect for damage listed below. Use a 3X to

5X power magnifying glass for inspection. If

cracks are suspected, use local dye-penetrant

inspection (TM 1-1500-335-23) to verify cracks.

a.

Cracks or dents on any areas of shaft (1). If

cracks or dents are found, replace the shaft.

If a crack is suspected in one piece engine

drive shaft, refer to TM 1-1520-253-23.

b.

Nicks, scratches, or gouges in outer 1.5

inches of each end of shaft. If defects are

found, replace the shaft, except as noted in

step 1c.

c.

Nicks and gouges up to 0.025 inch in depth

on the outer diameter of the shaft lug ears

(1.1). Blend out defects (Task 6-31.2). If

defects greater than 0.025 inch are found,

replace the shaft.

d.

Nicks, scratches, and gouges on center

section (2) of shaft, including balance flanges

(3). Blend out defects (Task 6-31.2).

2.

Check for corrosion or wear on inside surface

(4) of shaft, lug bushings (5), and lug bores (6).

Replace a shaft with corrosion or wear in these

areas.

6-92