TM 55-1520-240-23-5

6-30.3

INSPECT ONE-PIECE ENGINE DRIVE SHAFT (REMOVED)

(Continued)

6-30.3

3.

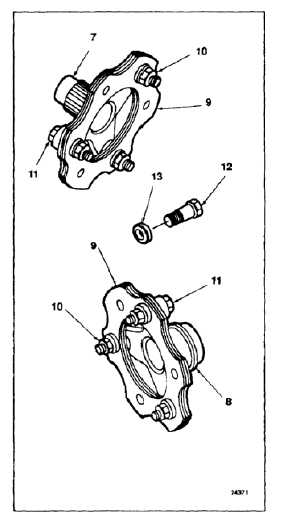

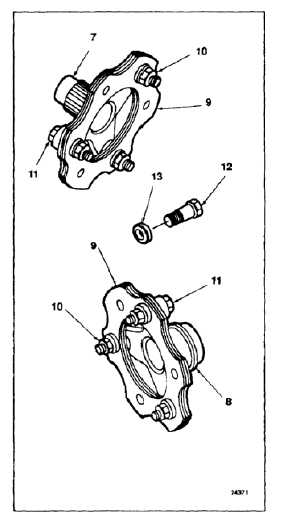

Inspect adapters (7 and 8) for cracks, nicks,

scratches, or gouges. Use a 3X to 5X power

magnifying glass for inspection. Replace any

cracked adapter assemblies. Remove any nicks,

scratches, or gouges by polishing (Task 6-31.2).

Do not loosen or remove more

than one bolt from the adapters at

the same time during inspection.

Adapters are balanced assemblies

and requires replacement if more than

one bolt is loosened or removed.

4.

Inspect adapter plates and attaching hardware

for damage listed below:

a.

Cracks nicks or gouges in visually accessible

areas of plates (9). Use a 3X to 5X power

magnifying glass to check. Give particular

attention to surfaces at exposed bolt holes.

Repair light scuffs, nicks, or scratches (Task

6-31.2). Normal adapter face or washer

contact pattern is permissible. Replace

adapter assemblies with any cracks. Replace

adapter assemblies with scratches, nicks, or

gouges in plates deeper than 0.001 inch. If

cracks are suspected in adapter plate, refer

to TM 1-1520-253-23.

b.

Nicks on inside edges of plates (9). Use a

pointed scribe to check. Replace nicked

adapter assemblies.

c.

Cracked nuts (10) and bolts (11). Replace

cracked nuts and bolts.

d.

Thread damage, fretting, gouges, wear steps,

and circumferential scoring on shaft attaching

bolts (12). If defects are found, refer to Task

6-31.2.

e.

Nicks, gouges, and fretting on bevel washers

(13). If defects are found, refer to Task 6-31.2.

6-93