TM 55-1520-240-23-4

5-93

INSTALL SHOCK ABSORBER (Continued)

5-93

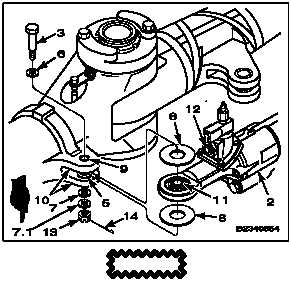

CONNECT SHOCK ABSORBER AT INBOARD LUGS

(WITHOUT 50 AND WITH 58 )

WARNING

Make sure blade is supported by sling

during installation; otherwise, damage

to helicopter or injury to personnel

could result.

CAUTION

Do not mix elastomeric bearings

with Teflon bearings on inboard end

of shock absorbers (With 45 ). If

elastomeric bearings are installed

in inboard end of shock absorber,

bushings 114H6803-2 must be

installed in shock absorbers.

NOTE

Aircraft/rotor heads (With 58 )

installed or "SK" behind the part

number can have either elastomeric

or Teflon bearing shock absorber/lag

dampers installed. Bolt (3) can either

be part number BACB30ST1239, or

145R3119-3, or bolt 145R3650-4 with

the bushing removed from the bolt.

5.

Install shock absorber (2) with bearing (11) and

two Teflon washers (8) between inboard lugs

(10). Face sight indicator (12) up and inboard.

6.

Install countersunk washer (6) on bolt (3), with

countersink toward bolthead.

6.1.

Before torquing bolts for shock absorbers (With

45 ) position the blade over the tunnel cover and

install the lead lag tool (T72). This removes the

load of the blade and prevents uneven torquing

with elastomeric bearings.

CAUTION

Positive retention bolts are installed in

shock absorber bearings. These bolts

require special torque (Task 1-14).

Do not torque bolt until a qualified

inspector has verified that sliding

bushing (5) is installed.

Antiseize compound on thread of bolt

or nut may result in over-torquing.

(With 45 ) Uneven torquing of

elastomeric bearings could cause the

bearing to become unseated during

flight.

7.

Align holes in lugs (10) and bearing (11). Install

bolt (3) and washer (7).

7.1.

Check that there is no antiseize compound on

thread of nut (13). Install nut on bolt (3). Torque

nut to 110-250 foot-pounds. Install cotter pin

(14). Washer (7) may be added to align cotter

pin.

NOTE

Use AN960-1216 and/or

AN960-1216L washers (7.1) between

nut (13) and MS20002-12 washer (7)

as required to align cotter pin hole in

bolt (3) with slot in nut (13).

7.2.

Check that Teflon washers (8) are not caught

between bearing (11) and bushings (5 or 9).

After torque application, the Teflon washers must

be free to turn.

5-560

Change 2