TM 55-1520-240-23-4

5-46

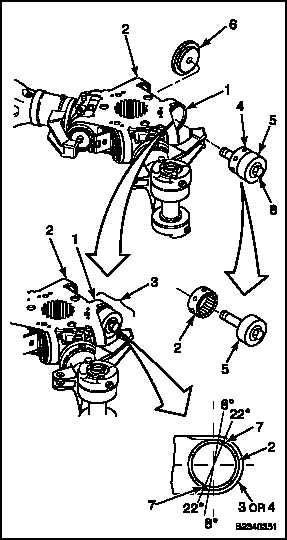

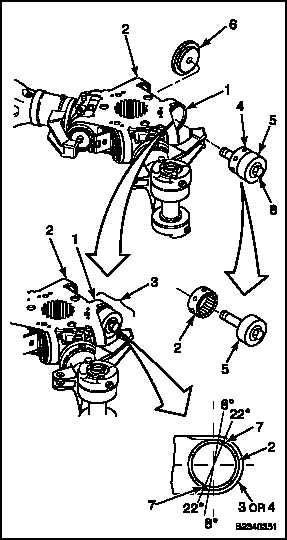

INSTALL HORIZONTAL HINGE PIN, PITCH-VARYING HOUSING, AND PIN

BEARINGS (Continued)

5-46

WARNING

These are installation critical flight

safety parts. All aspects of their

assembly and installation must be

ensured.

Ensure that specified installation tools

are used to preclude damage to lugs.

Ensure that lugs are heated to

specified temperature to ease

installation and minimize chances of

damaging lugs.

Ensure that the proper bearing is

installed in the appropriate lug. Lead

lug and lag lug take different bearings.

Ensure that pitch housing to be

installed is the same pitch housing

that was removed. Installation of

replacement pitch housings is not

permitted at this level.

Ensure that all rollers are in the cages

of the pitch bearings.

Ensure that the tie-bar pins are

installed and properly seated and

that the correct retention hardware is

installed and tightened to the proper

torque value.

NOTE

Procedure is similar to install any

horizontal hinge pin, pitch-varying

housing, and bearing assembly. There

are three horizontal hinge pins, six

pin bearings, and three pitch-varying

housings on a rotary-wing head.

Forward head is shown here.

When installing new lead and lag

horizontal hinge pin bearing, use the

preferred bearings 114RS225-1 (lead)

and 114RS226-1 (lag).

INSTALL HORIZONTAL HINGE PIN BEARINGS

CAUTION

Horizontal hinge pins with serial

numbers of UW2407 and prior that do

not have a suffix "A" vibro engraved

after the serial number and with total

time since new of 4800 flight hours

or more must be replaced.

1.

Heat lugs (1 and 2) to 250 F (121 C). Use heat

gun. Monitor temperature. Use temperature

indicating strips (E413). Wear gloves (E187).

5-198

Change 2