TM 55-1520-240-23-4

5-45

INSPECT HORIZONTAL HINGE PIN AND BEARINGS

(Continued)

5-45

3.

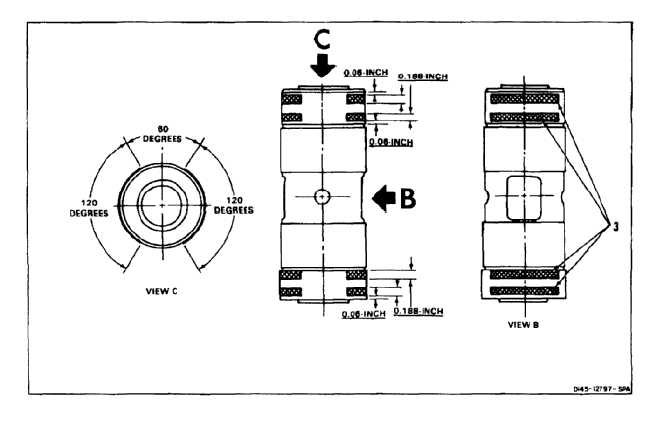

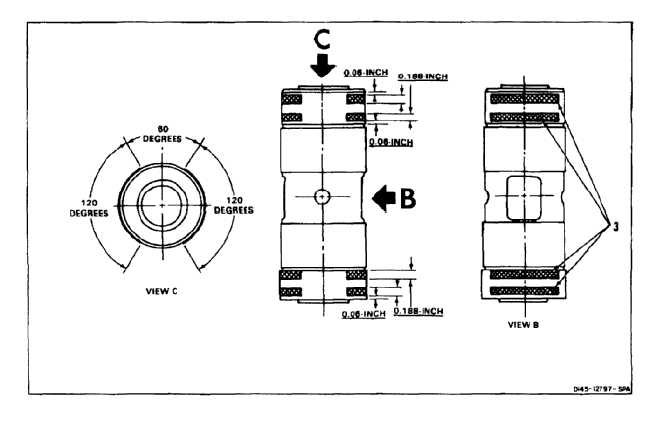

Check critical carburized areas (3) of horizontal

hinge pin (1) for pits, dents, nicks, scratches,

scuffs, rust, or corrosion. Critical carburized

areas (3) shall have none of these defects.

4.

Fluorescent inspect entire carburized areas of

pin (1) (TM 1-1500-335-23). Replace any pin

with cracks.

NOTE

A gap up to 0.50 inch between the

leading end sleeve (the sleeve with

the chamfer) and the leading edge of

pin is acceptable. Fill the gap with

sealing compound (E336) if sealing

compound is missing. Gap is caused

by the optional chamfer allowed on

leading end of pin during manufacture.

5.

Inspect all areas of pin (1), except critical areas

(steps 2 and 3) as follows:

a.

Check for pits. Pits shall not be greater than

0.030 inch wide, or 0.030 inch deep. There

shall be no more than three pits in a 0.25

inch circle.

b.

Check for dents or nicks. Dents or nicks shall

not be more than 0.060 inch wide nor 0.010

inch deep.

c.

Check for scratches or scuffs. Scratches or

scuffs in direction around pin (1) shall not

be more than 0.50 inch long. Scratches or

scuffs in direction of length of pin shall not be

more than 1.0 inch long. Scratches may not

be more than 0.003 inch deep, nor 0.006

inch wide. Scratches or scuffs on either face

of pin less than 1.0 inch long and less than

0.10 inch deep are acceptable.

5-195