TM 55-1520-240-23-4

5-45

INSPECT HORIZONTAL HINGE PIN AND BEARINGS

(Continued)

5-45

NOTE

A worn cage which permits rollers to

be loose or fall out is not cause for

bearing rejection.

6.

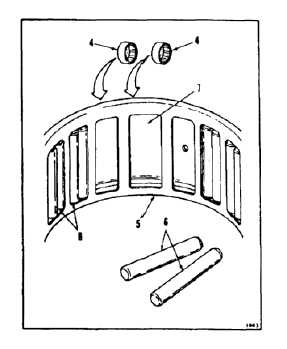

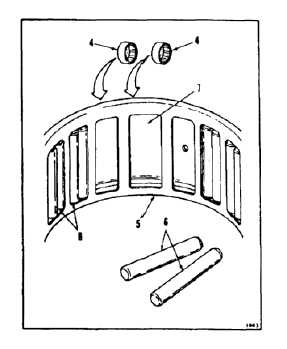

Inspect bearings (4) as follows:

a.

Check bearings (4). There shall be no cracks,

steel debris, spalling, damage or corrosion.

NOTE

Nicks, scratches, pitting, and

discoloration on non-working surfaces

are allowed. Fine copper or steel

residue from the thrust washer is

considered normal.

b.

Check that bearings (4) turn freely without

roughness.

c.

Check for damaged cages (5). These are

not permitted.

d.

Tap out several rollers (6). Use drift through

oil hole in bearing (4).

e.

Check for smearing, indentations, or

corrosion in raceways (7) or an rollers (6).

These are not permitted.

f.

Check for flaked or spalled load-carrying

surfaces. These are not permitted.

g.

Install rollers (6).

FOLLOW-ON MAINTENANCE:

None

END OF TASK

5-196