TM 55-1520-240-23-4

5-37

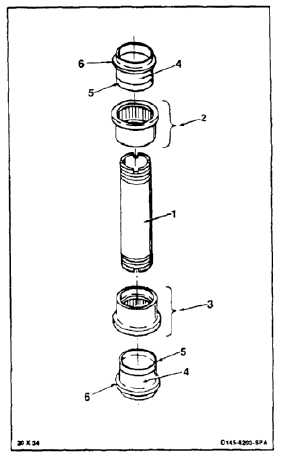

INSPECT VERTICAL HINGE PIN AND BEARINGS

5-37

INITIAL SETUP

Applicable Configurations:

All

Tools:

Technical Inspection Tool Kit, NSN 5180-00-323-5114

Drift, Aluminum 0.0625 x 6 Inches

Materials:

None

Personnel Required:

Inspector

References:

TM 1-1520-253-23

Equipment Condition:

Off Helicopter Task

Vertical hinge pins shall have the

letters EC following the serial number.

1.

Check the surface of vertical pin (1), upper

bearing (2), and lower bearing (3) for damage.

Damage can be removed by polishing. Use

abrasive paper (E8). It is not necessary to

remove the entire score or mark. Vertical scores,

circumferential marks, and corrosion pits less

than 0.005 inch depth are acceptable after

polishing provided all protruding edges have

been removed and the surface is smooth to the

touch. Light scratches are acceptable regardless

of direction. Definitions of a scratch and a score

as applicable to the vertical pin are as follows:

a.

Scratches are defined as equal to or less than

the depth and severity of scratches inflicted

by hand rubbing the part with abrasive paper

(E5).

b.

Scratches of greater depth or severity

than those described in step a above, are

considered scores.

2.

Check wear surfaces (4) of inner races (5) for

spalling, corrosion, or other damage. There shall

be no spalling or corrosion. There shall be no

scores or other marks deeper than 0.005 inch.

Scores and circumferential marks not deeper

than 0.005 inch may be blended out. Use

abrasive paper (E8). Any scratches not deeper

than those caused by abrasive paper (E5) are

acceptable without rework.

3.

Check upper and lower surfaces of flanges (6)

for cracks. There shall be no cracks. If a crack is

suspected, refer to TM 1-1520-253-23.

5-166