TM 55-1520-240-23-3

4-118

ADJUST ENGINE DROOP ELIMINATOR VARIABLE RESISTORS

(Continued)

4-118

RIG VARIABLE RESISTORS

NOTE

Adjustments for the No. 1 and the No.

2 resistors are the same. The No. 1

resistor is described.

Steps 12.1 thru 12.10 describes

the preferred method of rigging the

variable resistor because it checks

the active portion of the circuit and

the wiring from the resistor to the

control box. This has been added as

an option to steps 6 thru 12 which

checks only the inactive portion of the

variable resistor.

6.

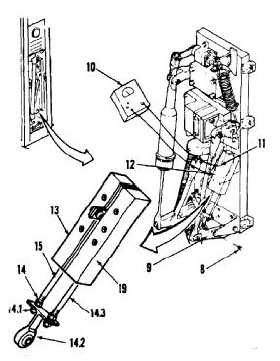

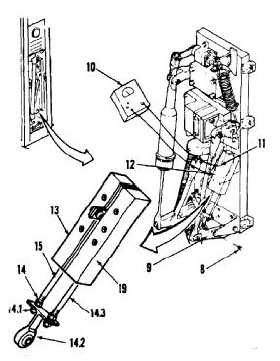

Install rig pin (T133) (8) in thrust control idler (9).

7.

Connect multimeter (10) to terminals 1 (11) and

2 (12) on No. 1 potentiometer (13).

8.

Check multimeter (10). If multimeter reads 31 to

35 ohms, go to step 13. If not, go to step 9.

9.

Loosen one nut (14) above and one nut (14.1)

below the link assembly on No. 1 potentiometer

shaft (15).

10.

Adjust shaft until multimeter reads 31 to 35

ohms. If multimeter reads 31 to 35 ohms, go to

step 10.2. If not, go to step 10.1.

10.1.

Check nuts for thread protrusion. If all threads

of nuts are not engaged, replace engine droop

eliminator potentiometer (13 and 19) (Task 4-119

and 4-122).

10.2.

Make sure link assembly (14.2) is parallel to

resistor shafts (15 and 14.3).

10.3.

Tighten one nut (14) above and one nut (14.1)

below the link assembly (14.2). Apply Loctite to

one nut (14). Torque nuts to 25 inch-pounds.

11.

Disconnect multimeter (10) from terminals 1 (11)

and 2 (12). Go to step 13.

12.

Repeat steps 6 thru 11 for the No. 2

potentiometer (19).

4-413