TM 55-1520-240-23-9

11-235

INSTALL TUNNEL FORWARD CONNECTING LINKS (Continued)

11-235

WARNING

FLIGHT SAFETY PARTS

This is an installation critical flight

safety part. All aspects of its assembly

and installation must be ensured.

Ensure that both rod end jam nuts are

installed and torqued.

Ensure that the rivet through the fixed

rod end insert and rod end is secure.

Ensure rivet, roll pin, and associated

hardware through rod end insert at

adjustable end of link assy is secure.

Ensure proper application of ALBI fire

retardant coatings to the link assy.

Ensure the bushing is installed on

the bolt head side of the clevis on

the aft end of this link. Omission of

this bushing will result in improper

stack-up.

Ensure proper attaching hardware

(impedance type bolt, nut, and

washers) is installed including

verification of bolt head orientation,

torque, and installation of cotter pins.

Loose attachments within flight control

primary linkage will degrade aircraft

control. Missing components will

cause loss of control.

WARNING

FLIGHT SAFETY PARTS

This is an installation critical flight

safety part. All aspects of its assembly

and installation must be ensured.

Ensure that both rod end jam nuts are

installed and torqued.

Ensure that the rivet through the fixed

rod end insert is secure.

Ensure the bushing is installed on

the bolt head side of the clevis on

the aft end of this link. Omission of

this bushing will result in improper

stack-up.

Ensure proper attaching hardware

(impedance type bolt, nut, and

washers) is installed including

verification of bolt head orientation,

torque, and installation of cotter pins.

Loose attachments within flight control

primary linkage will degrade aircraft

control. Missing components will

cause loss of control.

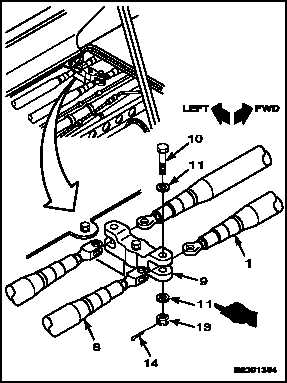

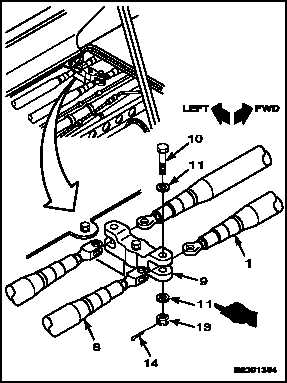

NOTE

Connecting links at STA 163.00 are

shown here. Black band end of a link

goes forward. Steel links, either end

forward.

4.

Ensure bearings are installed in control arm (9).

Position right forward connecting link (1) and

connecting link (8) in control arm (9).

5.

Install bolt (10), washer (11), and nut (13).

Torque nut to 60 to 90 inch-pounds. Install

cotter pin (14).

Change 1

11-917