TM 55-1520-240-23-9

11-221

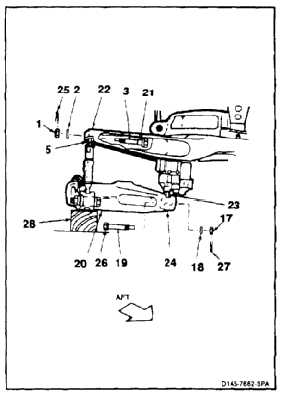

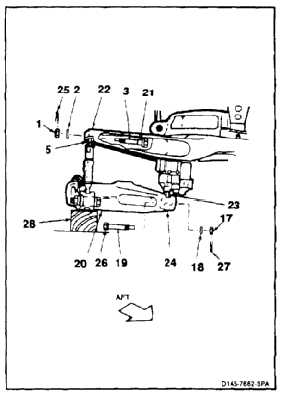

INSTALL AFT LCT ACTUATOR

(Continued)

11-221

8.

Apply antiseize compound (E75) to bushing (21)

on bolt (3). Keep compound off threads of bolts.

Wear gloves (E184.1).

9.

Have helper raise yoke (20). Guide rod end

bearing (5) into lug (22). Guide end fitting

bearing (23) into lug (24).

10.

Install bolt (3) head aft, through swashplate lug

(22) and connecting link rod end (5). Install

washer (2) and nut (1). Torque nut to 660 to 780

inch-pounds. Do not exceed 1400 inch-pounds

for cotter pin alignment. Install cotter pin (25).

11.

Install recessed washer (26) on bolt (19), recess

toward head. Install bolt dry, head forward,

through yoke lug (24) and actuator bearing (23).

Install washer (18) and nut (17).

12.

Torque nut (17) to 660 to 780 inch-pounds.

Continue tightening on for cotter pin hole

alignment. Do not exceed 1400 inch-pounds.

13.

Remove block (28).

INSPECT

FOLLOW-ON MAINTENANCE:

Perform rigging check of forward and aft longitudinal

cydic trim actuators (Task 11-40).

Connect aft rotor pitch links (Task 5-99).

Perform neutral rig check (Task 11-33).

Perform LCT actuator portion of AFCS operational

check (TM 55-1520-240-T).

Close pylon work platforms (Task 2-2).

END OF TASK

11-867