TM 55-1520-240-23-9

11-210

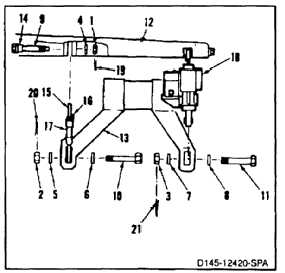

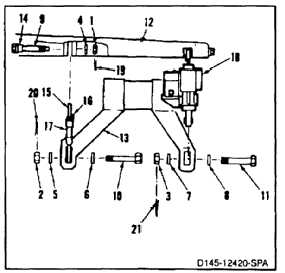

INSTALL FORWARD LCT CONNECTING LINK

(Continued)

11-210

3.

Position link rod end (15) in swashplate (12).

Alignment guide (16) shall face aft. Install bolt

(9), head forward, washer (4), and nut (1).

Torque nut to 400 to 660 inch-pounds, this

includes torque for alignment of the cotter pin. A

third washer, AN960C816 or AN960C816L may

be required for cotter pin alignment.

INSPECT

FLIGHT SAFETY PARTS

This is an installation critical flight

safety part. All aspects of its assembly

and installation must be ensured at

each joint connection and mounting to

the swashplate and yoke assembly.

Ensure locking tab washer is facing in

the proper direction.

Verify all required bushings are

installed in the associated clevis of

the yoke assembly and swashplate

stationary ring.

Ensure wire bundle is routed so as not

to interfere with flight control system

motions.

After applying nut torque, ensure

locking tab washer is lockwired to the

jam nut per BAC5018.

Ensure proper attaching hardware

(impedance type bolt, nut, and

washers) is installed including

verification of bolt head orientation,

torque, and installation of cotter pins.

Ensure special countersunk washers

are installed properly under the head

of self retaining bolts. Countersink

must face towards head of bolt.

Loose attachments within flight control

primary linkage will degrade aircraft

control. Missing components will

cause loss of control.

4.

Have helper raise yoke (13). Position end fittings

of link (17) and actuator (19) in lugs of yoke.

5.

Install washers (6 and 8) on bolts (10 and 11),

recess toward head.

6.

Install bolts (10 and 11), dry, heads aft, washers

(5 and 7), and nuts (2 and 3). Torque nuts to

290 to 660 inch-pounds, this includes torque

for alignment of the cotter pin. A third washer,

AN960C816 or AN960C816L may be required

for cotter pin alignment.

INSPECT

7.

Install cotter pins (19, 20, and 21).

INSPECT

11-834