TM 55-1520-240-23-9

11-80

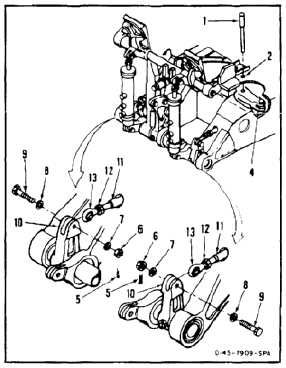

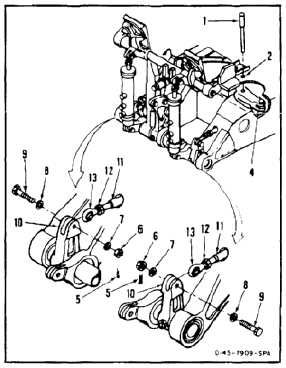

RIG PILOT’S COCKPIT CONTROL ASSEMBLY

(Continued)

11-80

2.

Loosen two nuts (12) of links (11).

3.

Remove two cotter pins (5), two nuts (6), two

washers (7), two washers (8), and two bolts

(9) from two arms (10). Disconnect two yaw

connecting links (11) from arms.

4.

Check that rigging pin (1) is fully inserted in hole

(2) through top of support assembly through yaw

bellcrank (4), and through hole (2) in bottom of

support assembly.

After adjusting rod ends insure that

safety holes of connecting links are

blocked to insure adequate thread

engagement.

5.

Turn two rod ends (13) until links (11) can be

positioned in arms (10) with bolts (9) freely

inserted. Check pin (1) is free with bolts inserted.

6.

Connect links (11) to arms (10). Install two bolts

(9), two washers (8), two washers (7), and nuts

(6).

7.

Torque two nuts (6) to 30 to 45 inch-pounds.

Install two cotter pins (5).

8.

Check two bolts (9). Bolts shall not rotate with

torque less than 10 inch-pounds. There shall be

no axial looseness. If bolt rotates or is loose, add

washer under nut and repeat step 7.

9.

Torque two nuts (12) to 103 inch-pounds.

10.

Remove rigging pin (1) from holes (2) and

bellcrank (4).

INSPECT

11-415