TM 55-1520-240-23-9

11-48

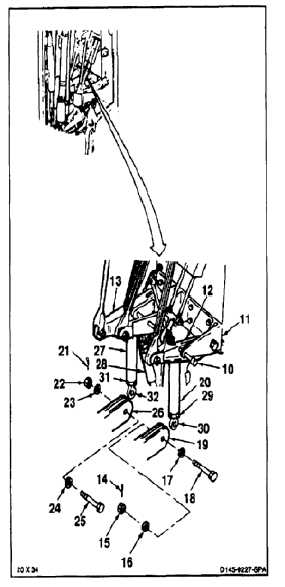

RIG PALLET THRUST AND YAW IDLER BELLCRANKS

(Continued)

11-48

6.

Remove cotter pin (14), nut (15), two washers

(16 and 17), and bolt (18) from pitch transfer

bellcrank (19). Disconnect thrust input link (20)

from bellcrank.

7.

Remove cotter pin (21), nut (22), two washers

(23 and 24), and bolt (25) from roll transfer

bellcrank (26). Disconnect yaw input link (27)

from bellcrank.

8.

Install pin (10) through support (11) and two

bellcranks (12 and 13). Pin must slide freely. If

not repeat steps 1, 8, and 3, then go to step 9.

9.

Adjust yaw position transducers (28 and 29)

(Task 11-176).

10.

Loosen nut (29) of link (20). Turn rod end (33)

until link can be positioned in bellcrank (19) with

bolt (18) installed loosely.

Bushings must be in bellcranks before

installing bolts; otherwise, damage to

components will result.

11.

Install bolt (18), two washers (17 and 16), and

nut (15) in bellcrank (19). Do not torque nut at

this time.

12.

Loosen nut (31) of link (27). Turn rod end (32)n

until link can be positioned in bellcrank (26) with

bolt (25) installed loosely.

13.

Install bolt (25), two washers (24 and 23), and

nut (22) in bellcrank (26).

14.

Torque two nuts (15 and 22) to 30 to 45

inch-pounds. Install two cotter pins (14 and 21).

15.

Torque two nuts (30 and 31) to 30 to 40

inch-pounds.

16.

Check two bolts (18 and 25). Bolts shall not

rotate with torque less than 10 inch-pounds.

There shall be no axial looseness. If bolt rotates

or is loose add washer under nut and repeat 14.

17.

Remove pin (10) from support (11).

11-203