TM 55-1520-240-23-9

11-47

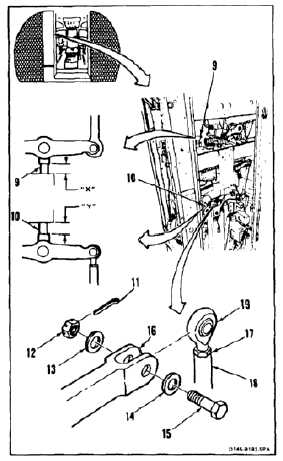

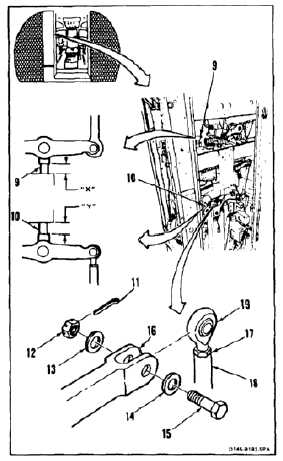

RIG ROLL, YAW OR THRUST ILCA INPUT CONNECTING LINKS

(Continued)

11-47

3.

Measure and record length ‘X’ of roll ILCA output

piston (9).

4.

Measure and record length ‘Y’ of roll ILCA input

piston (10).

5.

Check length ‘X’ and ‘Y’ for roll pistons (9 and

10). Subtract ‘X’ from ‘Y’. Difference must not be

more than 0.04 inches. If not more, go to step

14. If more, perform steps 6 thru 11.

6.

Remove cotter pin (11), nut (12), two washers

(13 and 14), and bolt (15) from roll ILCA input

arm (16).

Do not move input arm; otherwise,

damage to components may occur.

7.

Loosen nut (17) of link (18). Turn rod end (19)

one half turn.

NOTE

Turn rod end clockwise to increase

length ‘Y’.

8.

Position rod end (19) in arm (16). Install bolt (15)

loosely in arm.

9.

Repeat steps 3 and 4.

10.

Repeat step 5. If not more, perform step 11. If

more, repeat steps 7 thru 10.

11.

Remove bolt (15) from arm (16). Install bolt, two

washers (14 and 13) and nut (12) in arm.

12.

Torque nut (17) of link (18) to 103 inch-pounds.

13.

Torque nut (12) to 30 to 45 inch-pounds. Install

cotter pin (11).

14.

Check bolt (15). Bolt shall not rotate with torque

less than 10 inch-pounds. There shall be no

axial looseness. If bolt rotates or is loose, add

washer under nut and repeat step 13.

11-198