TM 55-1520-240-23-9

11-42

RIG COCKPIT CONTROL ASSEMBLIES

(Continued)

11-42

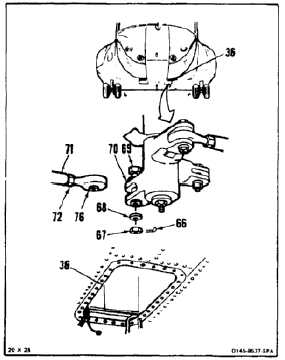

53.

Working through left access (36) turn rod end

(76) of link (71) until link can be positioned in

bellcrank (70) with bolt (69) installed loosely.

54.

Torque nut (72) of link (71) to 103 inch-pounds.

55.

Install bolt (69), washer (68), and nut (67) in

bellcrank (70).

56.

Torque nut (67) to 30 to 45 inch-pounds. Install

cotter pin (66).

57.

Check bolt (69). Bolt shall not rotate with torque

less than 10 inch-pounds. There shall be no

axial looseness. If bolt rotates or is loose, add

washer under nut and repeat step (56).

INSPECT

NEUTRAL ALIGNMENT CHECK

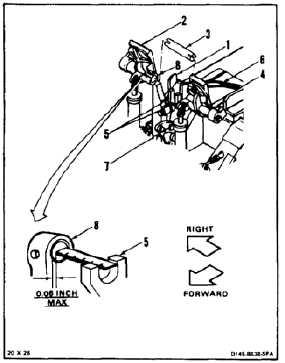

58.

Working in cockpit, slide pin (3) out of pilot’s

pedal tube (8). Press lever (1) and position right

pedal (2) forward. Release lever.

59.

Remove pin (3) from tube (4).

60.

Press lever (1). Pull pedal (2) aft to center

adjustment hole (7). Release lever.

61.

Check position of pedal tubes (4 and 8).

Measure tube positions from lugs (5) of fixture

(6). Distance must not be more than 0.06 inch

forward or aft. If distance is not more, go to step

62. If distance is more, repeat steps 1 thru 18,

then steps 58 thru 61.

11-172