TM 55-1520-240-23-9

11-32

RIG POSITION CHECK

(Continued)

11-32

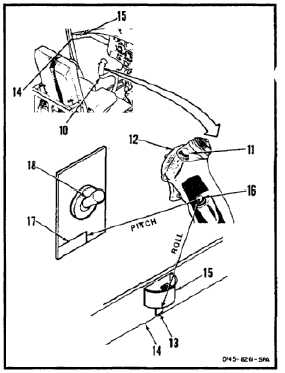

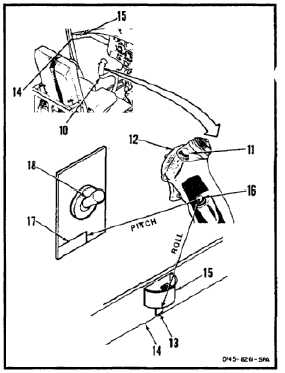

4.

Position copilot’s control stick (10) at neutral as

follows:

a.

Press CENTERING DEVICE RELEASE

button (11) on grip (12).

b.

Set ROLL distance given on label (13) of

side frame (14) under ashtray (15). Measure

distance between center of FLARE DISP

button (16) and mark on label (13).

c.

Set PITCH distance given on label (17) under

VGI switch (18) of copilot’s instrument panel.

Measure distance between center of button

(16) and mark on label (17).

d.

Release button (11).

INSPECT

Do not drive rig pin in rigging hole.

Damage to component will result.

Do not lubricate rig pin. Lubrication

will cause accumulation of dust at

rigging hole.

Do not move cockpit controls with

rig pin installed. Damage to pin and

component will result.

Do not stand, kick, or induce lateral

loads to the thrust idler. A cracked

arm will cause in-flight failure resulting

in disconnecting the thrust cockpit

driver actuator (CCDA) and the

droop eliminator potentiometers

(Without 74 ) or thrust control position

transducer (With 74 ).

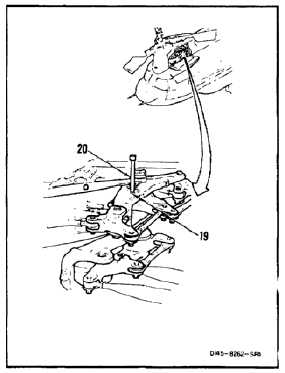

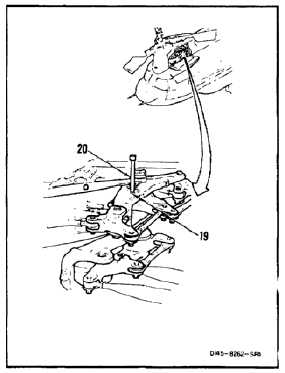

5.

Working from forward left work platform, align

second stage bellcrank rig pin hole (19). Have

helper in cockpit move pedals, control stick or

thrust control.

6.

Install rig pin (T135) (20). Pin must slide freely.

INSPECT

11-105