TM 55-1520-240-23-7

9-25.2

REPAIR AND TEST BATTERY CABLE (AVIM)

9-25.2

INITIAL SETUP

Applicable Configurations:

All

Tools:

Electrical Repairer’s Tool Kit, NSN 5180-00-323-4915

Battery Service Tool Kit, NSN 5180-00-542-5812

Exhaust Gas Temperature Tester (BH-112JB-53)

Heater Probe, BH22231

Multimeter (2)

Insulation Breakdown Test Set (AN/GSM-6), NSN

6625-00-5422-1331

Dial Indicating Scale, 0 to 10 Pounds

Compressed Air Source

Materials:

Boric Acid, ACS (E83)

Brush, Acid Swabbing (E86)

Cloth (E134)

Personnel Required:

Aircraft Electrician

References:

TM 11-6625-273-12

TM 11-6140-203-14-2

TM 55-4920-401-13&P

TM 55-1500-323-25

Equipment Condition:

Off Helicopter Task

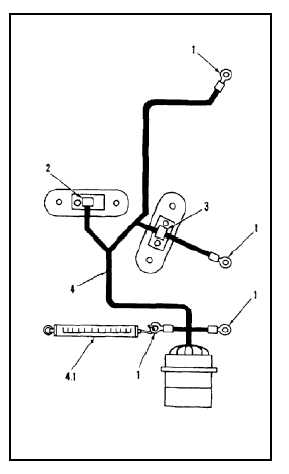

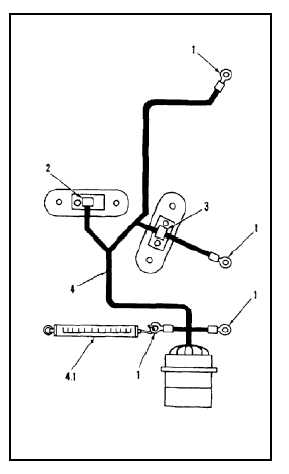

1.

Remove corrosion or foreign deposits from

terminals (1), thermal switch (2), thermistor (3),

and insulation. Use a mixture of 3 percent by

weight of boric acid (E83) and water, and a brush

(E86).

Do not use more than 30 psi

compressed air for cleaning purposes.

Debris trajected under pressure can

cause injury to eyes. Use source of

compressed air under 30 psi and

eye protection to prevent injury to

personnel.

2.

Thoroughly clean off battery cable (4) with tap

water and brush (E86). Do not immerse harness

assembly into water. Wipe harness with cloth

(E134) and dry off with dry compressed air as

necessary.

3.

Use dial indicating scale (4.1). Apply a 2.5

to 3.5 pound pull on each connection. If any

terminal comes off, replace it. Refer to TM

55-1500-323-25.

4.

Check battery cable wires. If any wire is

damaged, replace battery cable.

9-72